Novel technique for electrical activation of implanted material without co-implantation

Researchers at the Naval Research Laboratory in Washington, USA, have implanted Mg in GaN and employed a novel high-temperature annealing technique that has realised electrical activation of implanted material for the first time without co-implantation, and demonstrated an increase in the activation ratios for in situ Mg-doped GaN from around 1% to a record 10%.

Doping limitations

The GaN materials system, possessing a unique combination of both a high breakdown field and high electron mobility, is very attractive for high power and high frequency applications. Investment in AlGaN/GaN HEMT device research has led to a robust technology for RF power amplifiers.

Power device research, however, has been hindered by the lack of a selective-area p-type doping process, which is useful for a number of power switching devices including lateral p-n junctions and JFETs as well as edge termination for vertical switches. Although there are some lateral GaN power devices commercially available, these are still relatively low voltage parts which has limited the system-level adoption of this technology.

Mg is typically used for p-type doping but it is a relatively deep acceptor which limits the activation ratio and, when doping during epitaxial growth it tends to form complexes with hydrogen which further limits activation. Selective-area doping can be achieved by ion implantation but this causes damage to the lattice. In the 1990s many efforts were made to develop a high temperature annealing technique above the thermodynamic stability limits of GaN to recover this damage and electrically active the acceptors, but with no success.

Alternative processes are either conventional or microwave rapid thermal annealing at near-atmospheric pressures, which has the disadvantage of decomposing the surface; or high pressure annealing which needs equipment that is not amenable to large-area, high-throughput semiconductor processing.

Hotter for longer

In their work reported in this issue of Electronics Letters, the team at the Naval Research Laboratory report p-type doping by ion implantation using a new annealing approach that allows them to achieve a longer time at higher temperatures than previously possible.

"This approach represents a new paradigm in high temperature processing of semiconductors," said Travis Anderson, the lead author on the Letter. "By employing a combination of a protective cap structure, moderate overpressure and rapid cycling, we can overcome the stability limitations and accumulate a large time at temperatures sufficient to activate the dopants."

Previously, there have only been a few reports of p-type doping by ion implantation, and these have had very low activation ratios of less than 1%. This is limited by several factors: the activation energy for Mg is relatively high (160 meV), thus the number of ionised acceptors is inherently low; and Mg must occupy a Ga-site to be electrically active, therefore previous results have relied on phosphorous coimplantation to induce more Ga-vacancies. For epitaxial doping, the typical approach to activate p-type doping in GaN has been to load the crystal with extremely high amounts of Mg to overcome the low activation ratio. However, this large number of electrically inactive impurities inherently degrades crystal quality and can even cause phase segregation and polarity inversion.

The new method developed by the team of researchers allows for selective-area doping with a controlled carrier concentration, resulting in a much higher activation ratio of about 10%.

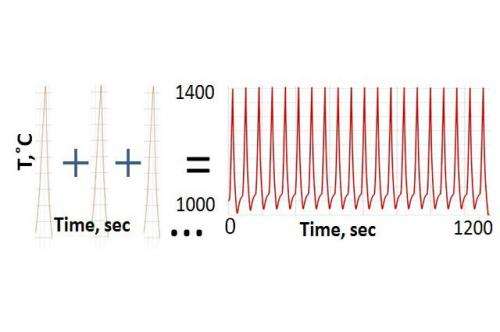

"The major challenge in this work was overcoming the thermodynamic stability limits of the GaN crystal," said Anderson. "Temperatures higher than 1400°C are required to activate Mg, but at atmospheric pressure the crystal will decompose at temperatures above 900 °C. We took the unique approach of applying an AlN cap structure and a nitrogen overpressure to stabilise the crystal at higher temperatures. This alone is still not sufficient to prevent decomposition when held for over 30 seconds, so we overcame this limitation by accumulating time at high temperature with a pulsed approach, which allows the crystal to recover and stabilise at temperatures near the equilibrium line between pulses."

Future drivers

The team have since been performing further characterisation of the materials to understand the mechanism for dopant activation and how the material responds to the new annealing process, as well as planning new experiments to optimise the implant and annealing conditions.

"Advances in dopant control/activation, as well as the availability of bulk GaN substrates, will drive development of vertical GaN power switching devices," said Anderson. "We also expect solid state lighting to continue to be a market driver for III-Nitrides, and to potentially benefit from an improved acceptor activation ratio."

More information: "Activation of Mg implanted in GaN by multicycle rapid thermal annealing." T.J. Anderson, B.N. Feigelson, F.J. Kub, M.J. Tadjer, K.D. Hobart, M.A. Mastro, J.K. Hite, C.R. Eddy Jr. Electronics Letters, Volume 50, Issue 3, 30 January 2014, p. 197 – 198. DOI: 10.1049/el.2013.3214 , Print ISSN 0013-5194, Online ISSN 1350-911X

Provided by Institution of Engineering and Technology