May 15, 2014 feature

One-nm-thick graphene engine mimics two-stroke engine

(Phys.org) —It may sound impossible that a 1-nm-thick piece of graphene—made of just a single layer of carbon atoms and containing some chlorine and fluorine atoms—can function as a two-stroke combustion engine. After all, on the macroscale, two-stroke engines are often used to power devices such as chainsaws and motorcycles. Although the nanoscale version is also very powerful, its potential applications in next-generation nanodevices would of course be very different.

Although micro/nano engine designs are often inspired by macroscopic engines, this is the first nanoscale engine that mimics an internal combustion engine, despite the widespread use of two- and four-stroke engines since the 19th century.

Researchers Jong Hak Lee, et al., from Prof. Barbaros Özyilmaz' group at the Graphene Research Center at the National University of Singapore, have published a paper on the tiny graphene engine in a recent issue of Nano Letters.

"The beauty of this approach is that our engine is very simple and has practically no byproducts (exhaust), neither do we need specific working conditions; therefore we believe that this is a viable engine for nanomachines for varied applications," Lee told Phys.org. "Similar to the one in everyday vehicles, a nano-motor or rotor which can generate directional motion at the nanoscale is essential for nanomachine or nanorobotic applications. Graphene has been known to have the highest strength among materials, which is very useful for this application. This is the first time anyone has explored graphene for such applications. So, we hope that our work will inspire other groups to come up with many more potential applications."

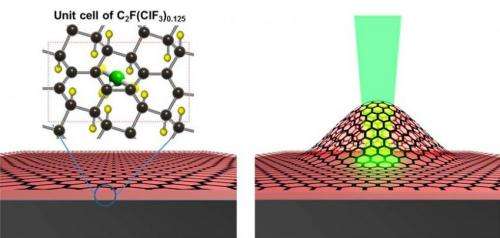

Whereas in a conventional two-stroke engine, a piston moves up and down to generate a high pressure, in the single-atom-thick layer of graphene, the graphene is itself the piston. When a laser beam irradiates a spot on the graphene, it causes the graphene to form a small dome-like blister. Rapidly turning the laser on and off causes the blister to repeatedly rise and become flat again, similar to the motion of a piston.

Part of the reason that this works is because of graphene's unique mechanical properties, especially its high elasticity and strength. But in order for the graphene engine to work, the researchers also had to insert chlorine fluoride (ClF3) molecules into the graphene lattice. The ClF3 molecules and carbon atoms in the graphene are held together by ionic carbon-fluorine bonds.

When exposed to the laser beam, these bonds dissociate, which leads to a rapid increase in pressure between the graphene and its substrate. This pressure is about 1 million Pa, which is several times higher than the average pressure of a car tire. The high pressure in turn leads to the formation of a blister. After the laser is turned off, the ClF3 molecules chemisorb back onto the graphene, the ionic bonds reform, the pressure decreases, and the blister disappears.

The scientists observed that the size of the blister varies with the laser power. For example, 0.32 mW laser power results in a blister with a diameter of about 550 nm. Above 8.5 mW of repeated cycling, the pressure becomes so high and the volume expansion so large that the blister bursts.

The researchers demonstrated that the graphene engine shows exceptional reliability. After 10,000 cycles, the engine continues to function with no degradation. The graphene engine is also highly energy efficient.

In the future, the researchers would like to improve the engine by exploring illumination parameters and on/off speed, as well as connect the engine to a target load. They also hope to investigate its various potential applications.

"As a simple application of this nanoengine, we could use this bulging motion of the graphene nanoengine as a pump or valve for a nanofluidic application," Lee said. "Ultimately, our new engine can be easily integrated into various applications by combining MEMS or NEMS techniques to transfer the generated force to each of the components. In the future, it can be easily implanted into nanorobots and other nanomachines."

More information: Jong Hak Lee, et al. "Nanometer Thick Elastic Graphene Engine." Nano Letters. DOI: 10.1021/nl500568d

Journal information: Nano Letters

© 2014 Phys.org