This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

trusted source

proofread

Costly gas separation may not be needed to recycle CO₂ from air and industrial plants

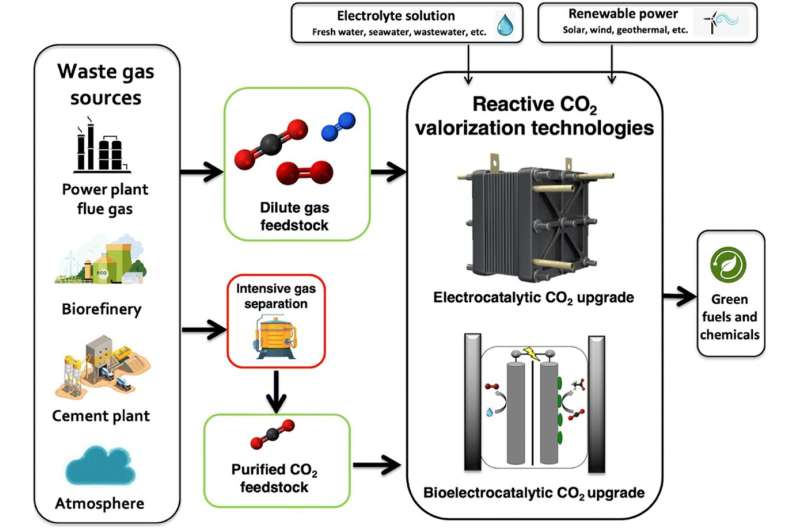

A costly step in the process of taking carbon dioxide emissions and converting them into useful products such as biofuels and pharmaceuticals may not be necessary, according to University of Michigan researchers.

The paper is published in the journal Environmental Science: Nano.

Carbon dioxide in the Earth's atmosphere is a key driver of climate change, with the burning of fossil fuels accounting for 90% of all CO2 emissions. New EPA regulations introduced in April call for fossil fuel plants to reduce their greenhouse gas emissions by 90% by 2039.

Many researchers argue that storing that CO2 would be a waste when carbon is needed to make many products we depend on daily, such as clothing, perfume, jet fuel, concrete and plastic. But recycling CO2 typically requires that it be separated from other gases—a process with a price tag that can be prohibitive.

Now, new kinds of electrodes, enhanced with a coating of bacteria, can skip that step. While conventional metal electrodes react with sulfur, oxygen and other components of air and flue gases, the bacteria seem less sensitive to them.

"The microbes on these electrodes, or biocatalysts, can use smaller concentrations of CO2 and seem more robust in terms of handling impurities when compared with electrodes that use metal catalysts," said Joshua Jack, U-M assistant professor of civil and environmental engineering, and first author of the paper on the cover of Environmental Science Nano.

"Platforms that use metals seem to be much more sensitive to impurities and often need higher CO2 concentrations to work. So if you wanted to take CO2 directly out of power plants' emissions, the biotic catalyst may be able to do it with minimal cleanup of that gas."

Because CO2 is one of the most stable molecules, getting the carbon away from the oxygen takes a lot of energy, delivered in the form of electricity. For example, metal electrodes take off one of the oxygen atoms, resulting in carbon monoxide, which can be fed into further reactions to make useful chemicals. But other molecules can react with those electrons as well.

The microbes, in contrast, can be much more targeted. They not only work together to remove oxygen, but with help from electrons provided by the electrode, they also begin building the carbon into more complex molecules.

To assess the potential cost savings from using biocatalysts to skip the gas separation step, Jack's team analyzed data from previous studies, establishing efficiency rates for converting different waste gases containing CO2. They then used that data to assess the carbon footprint and production costs for various CO2-derived products.

The results showed that using renewable electricity, like solar cells, with a concentrated CO2 source, without gas separation, allows for the lowest carbon footprint and most cost-competitive products.

But this ideal scenario is possible only for especially clean and concentrated CO2 sources, such as from fermentation at bioethanol plants. Separating CO2 from flue gases at fossil fuel burning operations can cost $40 to $100 per ton of CO2. And for exceptionally dilute sources such as regular air, the cost can reach $300 to $1,000 per ton.

The analysis showed that by using waste gases or air directly, recycling CO2 from dilute sources could become economically viable.

"Our hope is to accelerate the scalability of CO2 conversion technologies to mitigate climate change and improve carbon circularity," Jack said. "We want to rapidly decarbonize energy and now even the chemical industry, in a much faster timeframe."

More information: Joshua Jack et al, Electrified CO2 valorization in emerging nanotechnologies: a technical analysis of gas feedstock purity and nanomaterials in electrocatalytic and bio-electrocatalytic CO2 conversion, Environmental Science: Nano (2024). DOI: 10.1039/D3EN00912B

Provided by University of Michigan