Ultrathin silver films and lithographically patterned structures to enhance plasmonic performance

Plasmonic devices—such as superlenses, hyperlenses and plasmonic waveguides—have exciting potential for research and commercial applications because they permit optical lithography, imaging and waveguiding to be performed at resolutions below the diffraction limit of light. These devices often require low-loss ultrathin metal films, which are difficult to fabricate using current deposition techniques. Researchers have investigated processes such as seed layer deposition and thermal annealing to reduce the surface roughness and grain-boundary density of these films. To date, however, these processes have not been hugely successful.

Now, Ee Jin Teo and colleagues at the A*STAR Institute of Materials Research and Engineering, Singapore, the University of Hyogo, Japan, and the National University of Singapore have used gas cluster ion beam (GCIB) processing to smooth ultrathin metal films and thereby enhance their properties. A GCIB consists of thousands of gas molecules that are weakly bound by van der Waals forces. Such a beam is able to smooth out surface irregularities and reduce film thickness with nanometer precision. This processing significantly enhances surface plasmon resonance and propagation, and enables the fabrication of ultrathin films with extremely low electrical resistivity and optical loss.

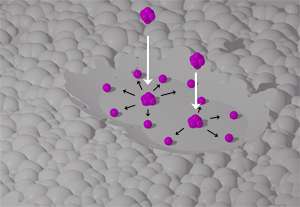

Unlike monomer ion beams used in conventional ion-beam milling and plasma etching, a cluster of nitrogen gas molecules with an energy of 20 kiloelectron volts impinging on a silver film can deliver a high energy density to a relatively small volume: yet the cluster penetrates to a depth of only a few nanometers. The impact of the beam on the film causes silver atoms in surface peaks to scatter sideways towards valleys, voids and grain boundaries. As well as producing a smoother surface, this processing triples the grain width through the redeposition of atoms at grain boundaries.

The team's GCIB treatment resulted in up to a four-fold improvement in the electrical and optical properties of films of a thickness of 12 nanometers. "The unique characteristics of GCIB irradiation meant that in a single irradiation step we could reduce scattering losses due to surface roughness, grain boundaries and voids," notes Teo.

The research team also used the technique to smooth the top surface and sidewalls of lithographically patterned silver-stripe waveguides, increasing the propagation lengths of surface plasmons in these waveguides.

"In the future, we intend to use this technique to improve the color purity of plasmonic color filters or reflectors, and also to increase the patterned area of superlens nanolithography," says Teo. "Such developments will bring plasmonic research a step closer to commercialization."

More information: Teo, E. J., Toyoda, N., Yang, C., Wang, B., Zhang, N. et al. "Sub-30 nm thick plasmonic films and structures with ultralow loss." Nanoscale 6, 3243–3249 (2014). dx.doi.org/10.1039/c3nr05502g

Journal information: Nanoscale