Inspired by nature, researchers create tougher metal materials

(Phys.org) —Drawing inspiration from the structure of bones and bamboo, researchers have found that by gradually changing the internal structure of metals they can make stronger, tougher materials that can be customized for a wide variety of applications – from body armor to automobile parts.

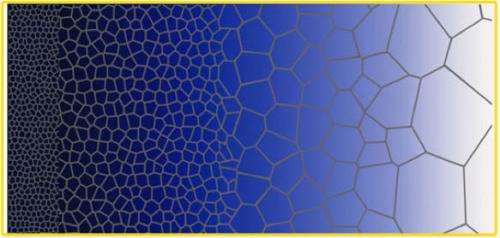

"If you looked at metal under a microscope you'd see that it is composed of millions of closely-packed grains," says Yuntian Zhu, a professor of materials science and engineering at NC State and senior author of two papers on the new work. "The size and disposition of those grains affect the metal's physical characteristics."

"Having small grains on the surface makes the metal harder, but also makes it less ductile – meaning it can't be stretched very far without breaking," says Xiaolei Wu, a professor of materials science at the Chinese Academy of Sciences' Institute of Mechanics, and lead author of the two papers. "But if we gradually increase the size of the grains lower down in the material, we can make the metal more ductile. You see similar variation in the size and distribution of structures in a cross-section of bone or a bamboo stalk. In short, the gradual interface of the large and small grains makes the overall material stronger and more ductile, which is a combination of characteristics that is unattainable in conventional materials.

"We call this a 'gradient structure,' and you can use this technique to customize a metal's characteristics," Wu adds.

Wu and Zhu collaborated on research that tested the gradient structure concept in a variety of metals, including copper, iron, nickel and stainless steel. The technique improved the metal's properties in all of them.

The research team also tested the new approach in interstitial free (IF) steel, which is used in some industrial applications.

If conventional IF steel is made strong enough to withstand 450 megapascals (MPa) of stress, it has very low ductility – the steel can only be stretched to less than 5 percent of its length without breaking. That makes it unsafe. Low ductility means a material is susceptible to catastrophic failure, such as suddenly snapping in half. Highly ductile materials can stretch, meaning they're more likely to give people time to respond to a problem before total failure.

By comparison, the researchers created an IF steel with a gradient structure; it was strong enough to handle 500 MPa and ductile enough to stretch to 20 percent of its length before failing.

The researchers are also interested in using the gradient structure approach to make materials more resistant to corrosion, wear and fatigue.

"We think this is an exciting new area for materials research because it has a host of applications and it can be easily and inexpensively incorporated into industrial processes," Wu says.

The work is described in two recently published papers: "Synergetic Strengthening by Gradient Structure," which was published online July 2 in Materials Research Letters, and "Extraordinary strain hardening by gradient structure," which is published in Proceedings of the National Academy of Sciences.

More information: "Synergetic Strengthening by Gradient Structure" Authors: X.L. Wu, P. Jiang, L. Chen, J.F. Zhang and F.P. Yuan, Chinese Academy of Sciences; Y.T. Zhu, North Carolina State University Published: online July 2, Materials Research Letters. DOI: 10.1080/21663831.2014.935821

Abstract: Gradient structures are characterized with a systematic change in microstructures on a macroscopic scale. Here we report that gradient structures in engineering materials such as metals produce an intrinsic synergetic strengthening, which is much higher than the sum of separate gradient layers. This is caused by macroscopic stress gradient and the bi-axial stress generated by mechanical incompatibility between different layers. This finding represents a new mechanism for strengthening that exploits the principles of both mechanics and materials science. It may provide for a new strategy for designing material structures with superior properties.

"Extraordinary strain hardening by gradient structure" Authors: X.L. Wu, P. Jiang, L. Chen and F.P. Yuan, Chinese Academy of Sciences; Y.T. Zhu, North Carolina State University Published: online May 5, Proceedings of the National Academy of Sciences DOI: 10.1073/pnas.1324069111

Abstract: Gradient structures have evolved over millions of years through natural selection and optimization in many biological systems such as bones and plant stems, where the structures gradually change from the surface to interior. The advantage of gradient structures is their maximization of physical and mechanical performance while minimizing material cost. Here we report that the gradient structure in engineering materials such as metals renders a unique extra strain hardening, which leads to high ductility. The grain size gradient under uniaxial tension induces a macroscopic strain gradient and converts the applied uniaxial stress to multi-axial stresses due to the evolution of incompatible deformation along the gradient depth. Thereby accumulation and interaction of dislocations are promoted, resulting in an extra hardening and an obvious strain hardening rate up-turn. Such extraordinary strain hardening, which is inherent to gradient structures and does not exist in homogeneous materials, provides a novel strategy to develop strong and ductile materials by architecting heterogeneous nanostructures.

Journal information: Proceedings of the National Academy of Sciences

Provided by North Carolina State University