Researchers develop an invisible type of bar code to thwart criminals

(Phys.org) —A team of researchers at Worcester Polytechnic Institute in Massachusetts has developed a type of bar coding system that would be almost impossible for criminals to thwart. As the team describes in their paper published in the journal Scientific Reports, the new system is based on adding certain types of nanoparticles to materials as part of the manufacturing process that can be read later using a special device.

Everyone is familiar with bar codes, they allow for quick scanning at checkout counters. But they are also used to track the movement of merchandise and in some cases, to prove that criminals have been counterfeiting products. Unfortunately for manufacturers, printed bar codes are relatively easy to reproduce, thus, criminals can make their own, allowing them to proceed with their illicit activities. In this new effort, the researchers have come up with a way to allow for the creation of invisible bar codes that are nearly impossible to replicate after the fact.

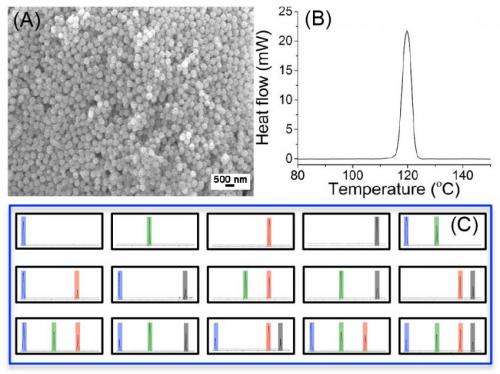

The idea revolves around several types of metal nanoparticles, each of which has a unique melting point. Mixing the nanoparticles together allows for creating unique thermal signatures. To use the nanoparticles, manufacturers would simply add them into the mix when creating metals, papers and even fluids. The researchers say the addition of the nanoparticles doesn't change how a material looks, doesn't react with anything in it or impact how a finished product performs. Reading the new type of "bar code" requires a device capable of performing differential scanning calorimetry (DSC)—a technique based on assessing the difference in the amount of heat required to heat different parts of a sample material. For criminals to circumvent the process they would have to somehow find out which nanomaterials were added to a product to create its unique thermal signature then add the right mix of nanoparticles to their own counterfeit product to recreate it—no easy feat.

The researchers claim their nanoparticle bar codes could be used with paper, metals, fluids and even drugs. As a demonstration, the team used their new technique on a sample of dinitrotoluene—one of the ingredients in TNT. They report being able to identify the thermal signature of the original mixture even after an explosion has occurred.

More information: Covert thermal barcodes based on phase change nanoparticles, Scientific Reports 4, Article number: 5170 DOI: 10.1038/srep05170

Abstract

An unmet need is to develop covert barcodes that can be used to track-trace objects, and authenticate documents. This paper describes a new nanoparticle-based covert barcode system, in which a selected panel of solid-to-liquid phase change nanoparticles with discrete and sharp melting peaks is added in a variety of objects such as explosive derivative, drug, polymer, and ink. This method has high labeling capacity owing to the small sizes of nanoparticles, sharp melting peaks, and large scan range of thermal analysis. The thermal barcode can enhance forensic investigation by its technical readiness, structural covertness, and robustness.

Journal information: Scientific Reports

© 2014 Phys.org