Marriage of nanocarbon and nanostructured porous carbon for next-generation batteries

By hybridizing sp2 nanocarbon and nanostructured porous carbon, researchers have created a high-energy and high-power lithium-sulfur battery at Tsinghua University, appearing on Volume 24, Issue 19 of Advanced Functional Material published on May 21, 2014.

"Motivated by the rapid development of portable electronics, electric vehicles, and renewable energy harvest, advanced energy storage devices such as lithium batteries are highly sought after," said Dr. Qiang Zhang, an associate professor at Department of Chemical Engineering, Tsinghua University. "Since the traditional lithium-ion battery has met its theoretical limitation for energy density, our group explored the tremendous potential of lithium-sulfur batteries, a novel electrochemical energy storage system, and has carried out wide research for about two years."

Lithium-sulfur batteries, employing sulfur as cathode and metallic lithium as anode, theoretically delivers energy density of 2600 Wh kg-1, three to six times higher than traditional lithium-ion batteries when sulfur and lithium are fully reacted. Additionally, the cathode material sulfur is naturally abundant, low cost, and environmentally friendly. However, there are still several challenge sto meet before lithium-sulfur batteries find practical application.

"On one hand, sulfur is highly electrical and ionic insulating. Its conductivity is several-to-ten orders of magnitude lower than typical LiCoO2 or LiFePO4 cathode material found in lithium-ion batteries, requiring 25 to 40 percent more weight in conductive agents within the whole cathode, thereby hindering the full demonstration of the intrinsic high energy density," Qiang told Phys.org,

"On the other hand, due to the multi-step and multi-phase reaction path, the high soluble intermediate, always in the form of chain-like polysulfide anions, generates at the cathode side, diffuses through the membrane, reacts with lithium anode, and shuttles back. During the whole process, polysulfides dissolve and irreversibly react with lithium and organic components, causing the destruction of the cathode structure, depletion of lithium anode, and loss of active materials. Thus, the life cycle is very poor."

Actually, similar to advanced anode material such as silicon and tin, there is a huge volume change (about 60-70 percent) when sulfur is fully lithiated into lighter lithium sulfide, resulting in the failure of the conductive scaffold and also the poor lifespan. To solve such multifaceted problems, researchers need to develop multifunctional material with high electrical conductivity, an interconnected ion pathway, and enough space for accommodating sulfur and retarding the diffusion of polysulfides.

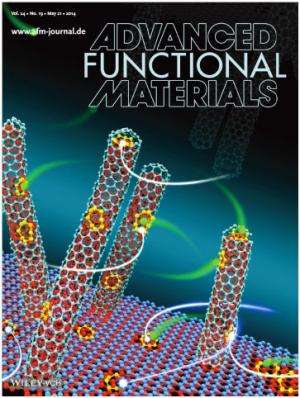

"Carbon material plays a vital role in advanced energy storage systems like lithium-sulfur batteries due to their excellent conductivity, mechanical flexibility, and tailored morphology and surface chemistry" said Prof. Fei Wei. "Our group has investigated nanocarbon material for a long time and developed a series of methodologies for mass production of carbon nanotubes (CNTs) and graphene, as well as their application for energy storage. The sp2 nanocarbon possesses extraordinary electron conductivity with limited specific surface area and confined space. Nanostructured porous carbon such as activated carbon and mesoporous carbon have high specific surface area and porosity but low conductivity due to the defective nature. Since both of the two cannot meet the requirement of lithium-sulfur batteries, the hybridization, or the 'marriage' of two such materials will result in a novel carbon nanoarchitecture inheriting the advantages and exhibiting superior functionality."

Based on this concept, Hong-Jie Peng, a graduate student and the first author, developed an in-situ chemical vapor deposition strategy followed by hydrocarbon pyrolysis and chemical activation. A CNT/graphene/porous carbon nanoarchitecture with extraordinary electrical conductivity and hierarchical micro-/mesopores was fabricated for an advanced carbon/sulfur composite cathode.The rational marriage of the two carbon materials realized the potential of carbon material as both electron/ion pathway and active mass reservoir. The resulting lithium-sulfur exhibited extended cycle life and superior power capability.

"We hope that the advanced carbon materials can help lithium-sulfur batteries to be comparable to the engine-driven system for future electric transportation." said Hong-Jie. Further study will focus on the increase of areal sulfur loading and actual content, as well as the innovation of membrane, anode, electrolyte, and the whole configuration of the cell. Additionally, the hybridized carbon material has amazing applications in supercapacitors, sodium-ion batteries, and metal-air batteries, and other technologies.

More information: Peng HJ, Huang JQ, Zhao MQ, Zhang Q, Liu XY, Qian WZ, Wei F. "Nanoarchitectured Graphene/CNT@Porous Carbon with Extraordinary Electrical Conductivity and Interconnected Micro/Mesopores for Lithium-Sulfur Batteries." Advanced Functional Materials 2014, 24(19), 2772-2781. DOI: 10.1002/adfm.201303296.

Journal information: Advanced Functional Materials

Provided by Tsinghua University