Probing metal solidification nondestructively

(Phys.org) —Los Alamos researchers and collaborators have used nondestructive imaging techniques to study the solidification of metal alloy samples. The team used complementary methods of proton radiography at the Los Alamos Neutron Science Center (LANSCE) and synchrotron x-ray radiography at Argonne National Laboratory (ANL) to make the measurements. This is the first time that high-energy protons have been used to nondestructively image a large metal sample during melting and solidification. Understanding the link between processing and structure is important because structure profoundly affects the properties and performance of engineering materials. Such real-time imaging could provide the insight needed to control the microstructure of metals and lead to advanced manufacturing processes to produce materials with desired properties. Scientific Reports published the research.

A metallic alloy solidifies over a range of temperatures and compositions. Historically, methods to design metal castings incorporated experimental trials in which researchers made castings and then cut up and polished the resulting parts to see the structure and to infer how processing influenced the material. Direct observations of metallic alloy solidification have been limited.

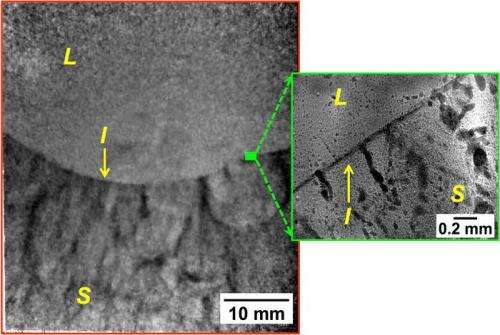

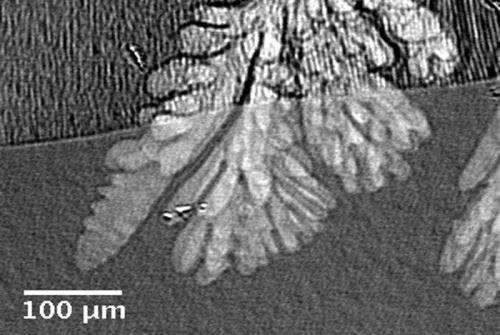

Scientists now can peer into a metal during processing without destroying it using high energy proton radiography (pRad) and synchrotron x-ray radiography. Amy Clarke of Metallurgy (MST-6) led a team that demonstrated the ability to use pRad, an imaging technique invented at Los Alamos, to examine large volumes (greater than 10,000 mm3) of metallic alloys during solidification. The researchers complemented the studies with local, higher resolution observations via synchrotron x-ray radiography, a technique that favors the examination of small volumes (less than 1 mm3) and low-density metals. Proton radiography enables direct observations of structural outcomes as a function of processing. It also affords studies of three-dimensional processes, such as fluid flow encountered during solidification for which thick sections, rather than thin (constrained) sections, better represent processes that occur in actual castings. This information bridges the micro- and macro- length scale regimes and provides insight into solidification processes.

These real-time imaging methods could enable efficient directed synthesis and processing to control structure evolution during solidification and the creation of optimal properties during process development. Experiments such as these could revolutionize our knowledge of metal casting and transform our ability to model these phenomena accurately.

The team used 800 MeV protons at LANSCE and synchrotron X-ray radiography at ANL's Advanced Photon Source to interrogate solidification in an alloy of aluminum with a 10 atomic percent indium addition. This alloy exists as two separate liquid phases before solidification. The scientists monitored the fluid flow and structure evolution in the experiments. The team made the first-ever pRad video sequence (avi) of the metal alloy melting and solidification. The minority and majority liquid phases behave similarly to oil droplets in water, except that the denser, indium-rich liquid droplets sink instead of floating in the majority aluminum-rich liquid phase as seen in this video (avi).

More information: "Proton Radiography Peers into Metal Solidification." Amy Clarke, et al. Scientific Reports 3, Article number: 2020 DOI: 10.1038/srep02020. Received 29 January 2013 Accepted 29 May 2013 Published 19 June 2013

Journal information: Scientific Reports

Provided by Los Alamos National Laboratory