Stain-free, self-cleaning clothing on the horizon

(Phys.org) —Since 2011, the Harvard research team that created Slippery Liquid-Infused Porous Surfaces has demonstrated a spate of sleek applications for the super-slick coating known as SLIPS, which repels nearly any substance it touches: water, ice, oil, saltwater, wax, blood, and more.

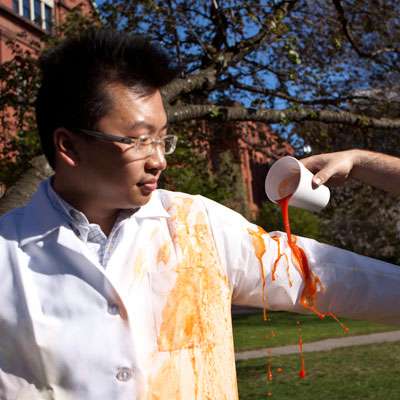

Now, SLIPS is wearable.

As reported January 10 in a special issue celebrating the 25th year of the journal Nanotechnology, the team has modified everyday cotton and polyester fabrics to exhibit traditional antifouling SLIPS behavior.

In past publications, the researchers at the Harvard School of Engineering and Applied Sciences (SEAS) and the Wyss Institute for Biologically Inspired Engineering have demonstrated SLIPS' versatility under extreme pH and temperature conditions, and have successfully coated diverse materials ranging from refrigeration coils to lenses, windows, and ceramics.

This latest advance could meet the need for a robust, stain-resistant textile for a host of consumer and industrial applications.

Most currently available state-of-the-art, stain-resistant fabrics draw their inspiration and design from the lotus leaf. Tiny nanotextures on the surface of lotus leaves resist water, causing droplets of water to bead up on a cushion of air at the edge of the surface. Lotus-inspired textiles therefore use air-filled nanostructures to repel water. These are capable of repelling most aqueous liquids and dirt particles, but they suffer from a series of shortcomings, explains Cicely Shillingford, a research assistant at the Wyss Institute and co-lead author of the Nanotechnology publication. They require a stable solid-air layer for the beading process to occur and thus fail easily under pressure—as in a heavy rainstorm—and do not withstand physical damage, such as twisting and abrasion, very well. They also stain more easily from organic or complex liquids, such as oil.

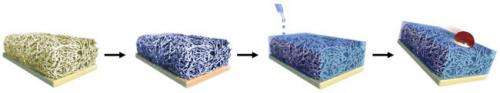

SLIPS, on the other hand, is inspired by the carnivorous pitcher plant, which locks in a water layer to create a slick coating that causes insects that land on it to literally hydroplane and fall into the plant. The SLIPS coating anchors a slippery lubricated film infused to a nanoporous solid surface, creating a material that performs exceedingly well under pressure or physical damage, and can resist all kinds of liquids, including oil.

"We took one page out of Nature's book, and are finding that it has the potential to help us develop solutions to a variety of age-old challenges: ice we don't want on refrigeration coils, bacteria that we don't want on medical devices, and now stains we don't want on clothes," says Joanna Aizenberg, Amy Smith Berylson Professor of Materials Science at SEAS and Professor of Chemistry and Chemical Biology. Aizenberg is also a Core Faculty Member at the Wyss Institute.

To create a fabric with SLIPS-type functionality, the team bought off-the-shelf cotton and polyester fabrics from stores near their lab in Cambridge, Mass., and developed two ways to chemically treat them. One involved coating them with tiny particles of silica (SiM), and the other required a treatment with sol-gel based alumina (SgB).

The team then put the SLIPS-fabrics through a ringer of tests performed according to industrial standards, including twisting, rubbing, and staining attempts.

"The SLIPS-fabric showed an unprecedented ability to repel a wide range of fluids and resist staining, and it handles physical stresses and strains just fine," says Aizenberg.

While not every SLIPS-fabric was as breathable (yet) as the researchers hoped, they outperformed currently available stain-resistant fabrics on just about every other measure. As such, the most likely immediate applications could be fabrics needed in potentially extreme environments where breathability is not paramount, but exposure to challenging contaminating liquids and biological hazards is involved, such as tactical suits for the military, lab coats, medical clothing, specialty garments for construction and manufacturing, and perhaps even tents and sports stadiums.

"We're very excited about the robustness of the SLIPS technology platform," Aizenberg says.

In 2012, Aizenberg's team won an R&D 100 Award for the technology from R&D Magazine. The award, given annually, honors the year's 100 most significant products, the so-called game-changers of the technology scene.

More information: (Phys.org) —"Fabrics coated with lubricated nanostructures display robust omniphobicity." Cicely Shillingford, Noah MacCallum, Tak-Sing Wong, Philseok Kim and Joanna Aizenberg. Nanotechnology 25 014019. DOI: 10.1088/0957-4484/25/1/014019

Journal information: Nanotechnology

Provided by Harvard University