Accelerated corrosion testing of silver provides clues about performance in atmospheric conditions

Small test strips made of silver or other metals, called "coupons," are frequently used to assess and predict the speeds at which metals used in outdoor environments—pipelines, aircraft, bridges, as well as countless other types of infrastructure and machinery—will succumb to corrosion.

"Silver is commonly used as a coupon, so it's important to understand what controls its corrosion rate," explains Gerald Frankel, director of the Fontana Corrosion Center, Department of Materials Science and Engineering, The Ohio State University.

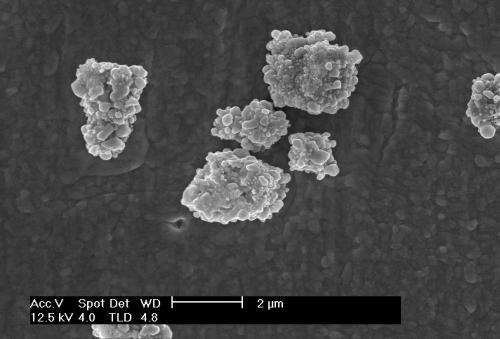

In a paper recently published in Corrosion journal, Frankel and co-author Huang Lin, a graduate research associate at the Fontana Corrosion Center, describe their work delving into accelerated atmospheric corrosion testing of silver in atmospheres containing humidity and ozone, with sodium chloride (salt) surface contamination and ultraviolet (UV) illumination.

By exploring the effects of all of these corrosive parameters on silver coupons in a "home-built" environment chamber, the researchers discovered that ozone, UV, and relative humidity all play significant roles in silver's corrosion rate.

Gaining a deeper understanding of the roles that the individual atmospheric parameters each play in influencing the corrosion rate of metals, such as silver, will enable the development of new models to better predict atmospheric corrosion rates and, ultimately, performance.

"Our work also involved finding appropriate accelerated lab tests to generate corrosion quickly, and then understanding how the performance of these tests might relate to the performance in real-world atmospheric conditions," Frankel notes.

Next, the researchers plan to study other metals that corrode uniformly, such as copper; and metals that corrode in a localized manner, such as aluminum alloys, painted metals, and galvanically coupled dissimilar metals.

More information: The paper, "Accelerated Atmospheric Corrosion Testing of Ag," written by Huang Lin and G.S. Frankel, appears in NACE International's journal, CORROSION, Nov. 2013, Vol. 69, No. 11, pp. 1060-1072: dx.doi.org/10.5006/0926

Provided by NACE International