3-D printer builds synthetic tissues

A custom-built programmable 3D printer can create materials with several of the properties of living tissues, Oxford University scientists have demonstrated.

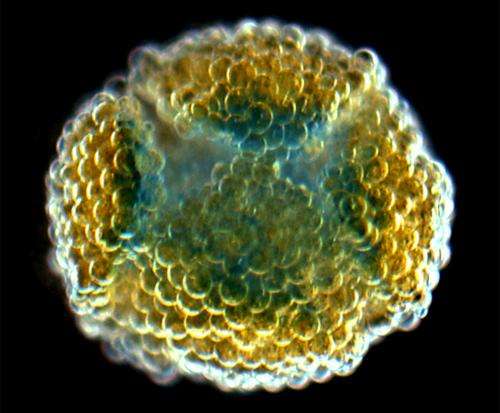

The new type of material consists of thousands of connected water droplets, encapsulated within lipid films, which can perform some of the functions of the cells inside our bodies.

These printed 'droplet networks' could be the building blocks of a new kind of technology for delivering drugs to places where they are needed and potentially one day replacing or interfacing with damaged human tissues. Because droplet networks are entirely synthetic, have no genome and do not replicate, they avoid some of the problems associated with other approaches to creating artificial tissues – such as those that use stem cells.

The team report their findings in this week's Science.

"We aren't trying to make materials that faithfully resemble tissues but rather structures that can carry out the functions of tissues," said Professor Hagan Bayley of Oxford University's Department of Chemistry, who led the research. 'We've shown that it is possible to create networks of tens of thousands connected droplets. The droplets can be printed with protein pores to form pathways through the network that mimic nerves and are able to transmit electrical signals from one side of a network to the other.'

Each droplet is an aqueous compartment about 50 microns in diameter. Although this is around five times larger than living cells the researchers believe there is no reason why they could not be made smaller. The networks remain stable for weeks.

"Conventional 3D printers aren't up to the job of creating these droplet networks, so we custom built one in our Oxford lab to do it,' said Professor Bayley. 'At the moment we've created networks of up to 35,000 droplets but the size of network we can make is really only limited by time and money. For our experiments we used two different types of droplet, but there's no reason why you couldn't use 50 or more different kinds."

The unique 3D printer was built by Gabriel Villar, a DPhil student in Professor Bayley's group and the lead author of the paper.

The droplet networks can be designed to fold themselves into different shapes after printing – so, for example, a flat shape that resembles the petals of a flower is 'programmed' to fold itself into a hollow ball, which cannot be obtained by direct printing. The folding, which resembles muscle movement, is powered by osmolarity differences that generate water transfer between droplets.

Gabriel Villar of Oxford University's Department of Chemistry said: "We have created a scalable way of producing a new type of soft material. The printed structures could in principle employ much of the biological machinery that enables the sophisticated behaviour of living cells and tissues."

More information: "A Tissue-Like Printed Material," by G. Villar et al, Science, 2013.

Journal information: Science

Provided by Oxford University