Manufacturing complex 3D metallic structures at nanoscale made possible

The fabrication of many objects, machines, and devices around us rely on the controlled deformation of metals by industrial processes such as bending, shearing, and stamping. Is this technology transferrable to nanoscale? Can we build similarly complex devices and machines with very small dimensions?

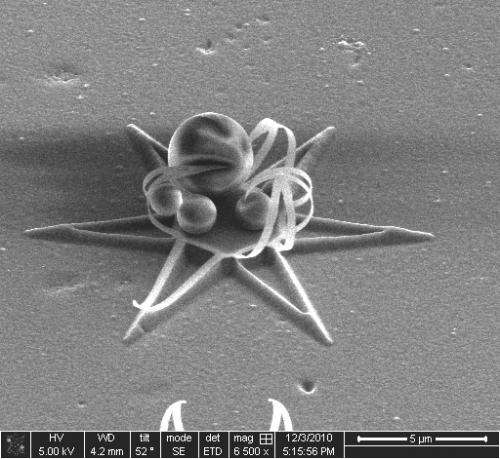

Scientists from Aalto University in Finland and the University of Washington in the US have just demonstrated this to be possible. By combining ion processing and nanolithography they have managed to create complex three-dimensional structures at nanoscale.

The discovery follows from a quest for understanding the irregular folding of metallic thin films after being processed by reactive ion etching.

"We were puzzled by the strong-width-dependent curvatures in the metallic strips. Usually initially-strained bilayer metals do not curl up this way," explains Khattiya Chalapat from Aalto University.

The puzzle began to unravel when Chalapat noticed, together with Dr. Hua Jiang, that the Ti peak was absent from the EDX spectra of folded Ti/Al bilayers.

Further experiments at the O.V. Lounasmaa Laboratory confirmed that the strips bend upward with strong width-dependent curvatures if the bottom layer of the strips is made more reactive to ions than the top surface.

In nature, similar geometrical effects take place in self-organization directly observable to the human eye. When dandelion flowers bloom, one may try cutting the flower stem into small strips; put them in water, and the strips will fold with observable width-dependent curvatures due to differences in the water absorption between the inside and outside parts of the stem.

"Our idea was to find a way to adapt these natural processes to nanofabrication. This led us to an incidental finding that a focused ion beam can locally induce bending with nanoscale resolution."

The technology has various applications in the fabrication of nanoscale devices. The structures are surprisingly resilient: the team found them to be quite sturdy and robust under a variety of adverse conditions, such as electrostatic discharge and heating.

"Because the structures are so small, the coupling and the magnitude of typical nanoscale forces acting on them would be commensurately small," reminds Docent Sorin Paraoanu, the leader of the Kvantti research group, Aalto University.

"As for applications, we have demonstrated so far that these structures can capture and retain particles with dimensions of the order of a micrometer. However, we believe that we are just scratching the tip of the iceberg: a comprehensive theory of ion-assisted self-assembly processes is yet to be reached," notes Paraoanu.

The research has been recently published in the Early View edition of Advanced Materials.

More information: onlinelibrary.wiley.com/doi/10 … a.201202549/abstract

Journal information: Advanced Materials

Provided by Aalto University