First all-carbon solar cell

(Phys.org)—Stanford University scientists have built the first solar cell made entirely of carbon, a promising alternative to the expensive materials used in photovoltaic devices today.

The results are published in the Oct. 31 online edition of the journal ACS Nano.

"Carbon has the potential to deliver high performance at a low cost," said study senior author Zhenan Bao, a professor of chemical engineering at Stanford. "To the best of our knowledge, this is the first demonstration of a working solar cell that has all of the components made of carbon. This study builds on previous work done in our lab."

Unlike rigid silicon solar panels that adorn many rooftops, Stanford's thin film prototype is made of carbon materials that can be coated from solution. "Perhaps in the future we can look at alternative markets where flexible carbon solar cells are coated on the surface of buildings, on windows or on cars to generate electricity," Bao said.

The coating technique also has the potential to reduce manufacturing costs, said Stanford graduate student Michael Vosgueritchian, co-lead author of the study with postdoctoral researcher Marc Ramuz.

"Processing silicon-based solar cells requires a lot of steps," Vosgueritchian explained. "But our entire device can be built using simple coating methods that don't require expensive tools and machines."

Carbon nanomaterials

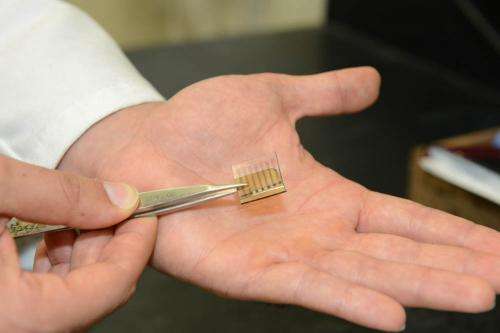

The Bao group's experimental solar cell consists of a photoactive layer, which absorbs sunlight, sandwiched between two electrodes. In a typical thin film solar cell, the electrodes are made of conductive metals and indium tin oxide (ITO). "Materials like indium are scarce and becoming more expensive as the demand for solar cells, touchscreen panels and other electronic devices grows," Bao said. "Carbon, on the other hand, is low cost and Earth-abundant."

For the study, Bao and her colleagues replaced the silver and ITO used in conventional electrodes with graphene – sheets of carbon that are one atom thick –and single-walled carbon nanotubes that are 10,000 times narrower than a human hair. "Carbon nanotubes have extraordinary electrical conductivity and light-absorption properties," Bao said.

For the active layer, the scientists used material made of carbon nanotubes and "buckyballs" – soccer ball-shaped carbon molecules just one nanometer in diameter. The research team recently filed a patent for the entire device.

"Every component in our solar cell, from top to bottom, is made of carbon materials," Vosgueritchian said. "Other groups have reported making all-carbon solar cells, but they were referring to just the active layer in the middle, not the electrodes."

One drawback of the all-carbon prototype is that it primarily absorbs near-infrared wavelengths of light, contributing to a laboratory efficiency of less than 1 percent – much lower than commercially available solar cells. "We clearly have a long way to go on efficiency," Bao said. "But with better materials and better processing techniques, we expect that the efficiency will go up quite dramatically."

Improving efficiency

The Stanford team is looking at a variety of ways to improve efficiency. "Roughness can short-circuit the device and make it hard to collect the current," Bao said. "We have to figure out how to make each layer very smooth by stacking the nanomaterials really well."

The researchers are also experimenting with carbon nanomaterials that can absorb more light in a broader range of wavelengths, including the visible spectrum.

"Materials made of carbon are very robust," Bao said. "They remain stable in air temperatures of nearly 1,100 degrees Fahrenheit."

The ability of carbon solar cells to out-perform conventional devices under extreme conditions could overcome the need for greater efficiency, according to Vosgueritchian. "We believe that all-carbon solar cells could be used in extreme environments, such as at high temperatures or at high physical stress," he said. "But obviously we want the highest efficiency possible and are working on ways to improve our device."

"Photovoltaics will definitely be a very important source of power that we will tap into in the future," Bao said. "We have a lot of available sunlight. We've got to figure out some way to use this natural resource that is given to us."

More information: pubs.acs.org/doi/full/10.1021/nn304410w

Journal information: ACS Nano

Provided by Stanford University