Researchers solve the mystery of nanowire breakage

Most materials will break when a force is applied to an imperfection in their structure—such as a notch or dislocation. The behavior of these imperfections, and the resulting breakage, differ markedly between small structures, such as nanowires, and larger, bulk materials. However, scientists lacked complete understanding of the precise mechanics of nanowire breakages, owing in part to inconsistent behavior in experiments. These inconsistencies are now resolved thanks to numerical simulations by Zhaoxuan Wu and his co-workers at the A*STAR Institute for High Performance Computing, Singapore, and collaborators in the US.

The researchers focused on metal nanowires with a so-called 'face-centered cubic crystal structure' because they exhibit two different failure modes. Previous experiments by other groups showed that these nanowires can break as the result of a ductile process, in which a narrow neck is formed smoothly and continuously before failure. Other experiments showed that the failure was caused by a brittle fracture, which happened suddenly. To complicate matters further, atom-scale simulations of these experiments predicted that only ductile necking should be occurring.

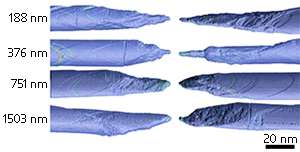

Wu and co-workers approached the problem by searching for a set of nanowire parameters that they could use to predict the type of failure. They used molecular dynamics software to simulate a series of cylindrical copper nanowires with a diameter of 20 nanometers and lengths ranging between 188 nanometers and 1,503 nanometers. They 'cut' a notch of 0.5 nanometers into the nanowire surface, which served as an initial deformation, and then applied tensile stress along the nanowire's long axis.

These simulations predicted that long nanowires were brittle and would fail abruptly, while short nanowires less than 1,500 nanometers in length were ductile and would exhibit a smooth deformation before failure. In other words, says Wu, they "fail gracefully". Previous nanowire simulations failed to identify these two regimes because the nanowire lengths considered were too short. The difference in behavior results from the fact that, for a given strain, long nanowires store a greater quantity of elastic energy than shorter wires.

This insight allowed Wu and co-workers to derive a simple expression for the length at which nanowires switch between failure modes. Both this expression, and the full simulation results, matched experimental data well. The results, says Wu, resolve an outstanding scientific issue, and provide a basic engineering principle for the design of nanoscale mechanical systems. Whether the model applies to nanowires with very small diameters, where classical plasticity effects begin to be lost, remains to be tested.

More information: Wu, Z., Zhang, Y.-W., Jhon, M. H., Gao, H. & Srolovitz, D. J. Nanowire failure: long = brittle and short = ductile. Nano Letters 12, 910–914 (2012). dx.doi.org/10.1021/nl203980u

Journal information: Nano Letters