SuperSTEM research reveals that graphene re-knits its holes

(Phys.org) -- Scientists at The University of Manchester and the SuperSTEM facility at STFC’s Daresbury Laboratory have discovered that the ‘miracle material’, graphene, undergoes a self repairing process to mend holes. This research, published in Nano Letters, could hold the key in the quest to realise graphene's huge potential for use in fields from electronics to medicine.

Graphene, which is made of sheets of carbon just one atom thick, is a promising material for a wide range of future applications due, for instance, to its exceptional electronic properties.

The team, which included Professor Kostya Novoselov, who shared a Nobel Prize in Physics in 2010 for exploiting the remarkable properties of graphene, was originally looking to gain a deeper understanding into how metals interact with graphene, essential if it is to be integrated into practical electronic devices in the future.

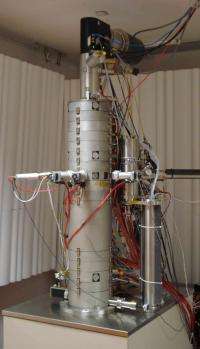

The researchers were using a powerful electron microscope at the SuperSTEM Laboratory at Daresbury, which allows scientists to study the properties of materials one atom at a time. They recently demonstrated that metals can initiate the formation of holes in the graphene sheet, which could be hugely detrimental to the properties of any graphene-based device.

Surprise results then showed that some of the holes that had been created during this process were actually mending themselves spontaneously using nearby loose carbon atoms to re-knit the graphene structure.

Dr. Quentin Ramasse, Scientific Director at SuperSTEM said: "This was a very exciting and unexpected result. The fact that graphene can heal itself under the right conditions may be the difference between a working device and a proof of concept without any real application. We may now have a way of not only drilling through graphene in a controlled fashion to sculpt it at the atomic level, but also to grow it back in new shapes. This adds a lot of flexibility to our nanotechnology toolbox and could pave the way to future technological applications".

More information: View the full paper online here.

Journal information: Nano Letters

Provided by Science and Technology Facilities Council