July 18, 2012 report

Researchers devise a way to a create graphene transistor

(Phys.org) -- Researchers in Germany appear to have found a way to create a monolithic (integrated) graphene transistor, using a lithographic process applied to silicon carbide, a breakthrough that could lead to computers based on graphene chips, rather than those that use silicon. This is significant because researchers are beginning to see the light at the end of the tunnel regarding the degree to which silicon can be used to make smaller and smaller chips. Using graphene wouldn’t necessarily allow for smaller chips, but because it conducts electricity faster, it would allow for faster chips without having to downsize. The German researchers working with another group from Sweden, describe the new process in their paper published in the journal Nature Communications.

By now everyone has heard that graphene is expected to take the world by storm over the next few years as ways are found to make use of its amazing properties (it’s just one carbon atom thick and is the fastest conductor ever found). The problem of course is in trying to work with such a thin material; it’s hard to connect to other metals such as electrodes and breaks easily. Another problem is that it’s not a natural semiconductor, which is a material that is conductive in one state and to not conductive in another. Semiconductors are what allow computers to store “1s” and “0s”. Thus, to use graphene in a computer, a way needs to be found to allow it to behave as a semiconductor so that transistors can be fashioned. That way appears to have now been found.

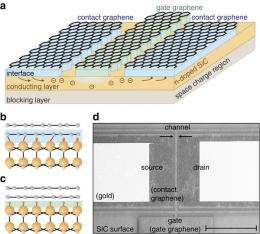

The new research is based on earlier research that found that if the crystal, silicon carbide is baked just right, the silicon atoms on its surface are pushed out of it leaving just a single layer of carbon, i.e. graphene. The result is a material that suggests a transistor is possible due to the graphene layer remaining affixed to more layers of silicon carbide (which is a semiconductor) below it. To make a transistor, the team used a high energy beam of charged atoms to etch channels into the material to create the parts needed for a transistor to run; namely, gates, drains and sources. They also found that using oxygen gas during the etching of the middle channel converted it from a contact into a gate. The end result is a fully functioning transistor.

Because the researchers scaled up the transistor size to allow for easier research, it’s not yet known how much faster the new transistor actually is, or how fast those might be once they are scaled down. What is now known though, is that it can be done, and that is the breakthrough computer engineers have been waiting for.

More information: Tailoring the graphene/silicon carbide interface for monolithic wafer-scale electronics, Nature Communications 3, Article number: 957 doi:10.1038/ncomms1955

Abstract

Graphene is an outstanding electronic material, predicted to have a role in post-silicon electronics. However, owing to the absence of an electronic bandgap, graphene switching devices with high on/off ratio are still lacking. Here in the search for a comprehensive concept for wafer-scale graphene electronics, we present a monolithic transistor that uses the entire material system epitaxial graphene on silicon carbide (0001). This system consists of the graphene layer with its vanishing energy gap, the underlying semiconductor and their common interface. The graphene/semiconductor interfaces are tailor-made for ohmic as well as for Schottky contacts side-by-side on the same chip. We demonstrate normally on and normally off operation of a single transistor with on/off ratios exceeding 104 and no damping at megahertz frequencies. In its simplest realization, the fabrication process requires only one lithography step to build transistors, diodes, resistors and eventually integrated circuits without the need of metallic interconnects.

Journal information: Nature Communications

© 2012 Phys.org