Nanofluidic 'multi-tool' separates and sizes nanoparticles

A wrench or a screwdriver of a single size is useful for some jobs, but for a more complicated project, you need a set of tools of different sizes. Following this guiding principle, researchers at the National Institute of Standards and Technology have engineered a nanoscale fluidic device that functions as a miniature "multi-tool" for working with nanoparticles -- objects whose dimensions are measured in nanometers, or billionths of a meter.

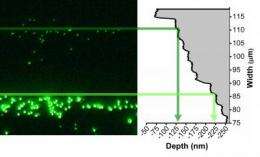

First introduced in March 2009 (see "NIST-Cornell Team Builds World's First Nanofluidic Device with Complex 3-D Surfaces", the device consists of a chamber with a cascading "staircase" of 30 nanofluidic channels ranging in depth from about 80 nanometers at the top to about 620 nanometers (slightly smaller than an average bacterium) at the bottom. Each of the many "steps" of the staircase provides another "tool" of a different size to manipulate nanoparticles in a method that is similar to how a coin sorter separates nickels, dimes and quarters.

In a new article in the journal Lab on a Chip, the NIST research team demonstrates that the device can successfully perform the first of a planned suite of nanoscale tasks—separating and measuring a mixture of spherical nanoparticles of different sizes (ranging from about 80 to 250 nanometers in diameter) dispersed in a solution. The researchers used electrophoresis—the method of moving charged particles through a solution by forcing them forward with an applied electric field—to drive the nanoparticles from the deep end of the chamber across the device into the progressively shallower channels. The nanoparticles were labeled with fluorescent dye so that their movements could be tracked with a microscope.

As expected, the larger particles stopped when they reached the steps of the staircase with depths that matched their diameters of around 220 nanometers. The smaller particles moved on until they, too, were restricted from moving into shallower channels at depths of around 110 nanometers. Because the particles were visible as fluorescent points of light, the position in the chamber where each individual particle was stopped could be mapped to the corresponding channel depth. This allowed the researchers to measure the distribution of nanoparticle sizes and validate the usefulness of the device as both a separation tool and reference material. Integrated into a microchip, the device could enable the sorting of complex nanoparticle mixtures, without observation, for subsequent application. This approach could prove to be faster and more economical than conventional methods of nanoparticle sample preparation and characterization.

The NIST team plans to engineer nanofluidic devices optimized for different nanoparticle sorting applications. These devices could be fabricated with tailored resolution (by increasing or decreasing the step size of the channels), over a particular range of particle sizes (by increasing or decreasing the maximum and minimum channel depths), and for select materials (by conforming the surface chemistry of the channels to optimize interaction with a specific substance). The researchers are also interested in determining if their technique could be used to separate mixtures of nanoparticles with similar sizes but different shapes—for example, mixtures of tubes and spheres.

More information: S.M. Stavis, J. Geist and M. Gaitan. Separation and metrology of nanoparticles by nanofluidic size exclusion. Lab on a Chip, forthcoming, August 2010.

Provided by National Institute of Standards and Technology