Scientists discover new principle in material science

(PhysOrg.com) -- Materials scientists have known that a metal's strength (or weakness) is governed by dislocation interactions, a messy exchange of intersecting fault lines that move or ripple within metallic crystals. But what happens when metals are engineered at the nanoscale? Is there a way to make metals stronger and more ductile by manipulating their nanostructures?

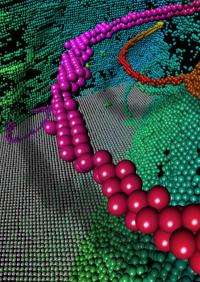

Brown University scientists may have figured out a way. In a paper published in Nature, Huajian Gao and researchers from the University of Alabama and China report a new mechanism that governs the peak strength of nanostructured metals. By performing 3-D atomic simulations of divided grains of nanostructured metals, Gao and his team observed that dislocations organize themselves in highly ordered, necklace-like patterns throughout the material. The nucleation of this dislocation pattern is what determines the peak strength of materials, the researchers report.

The finding could open the door to producing stronger, more ductile metals, said Gao, professor of engineering at Brown. "This is a new theory governing strength in materials science," he added. "Its significance is that it reveals a new mechanism of material strength that is unique for nanostructured materials."

Divide a grain of metal using a specialized technique, and the pieces may reveal boundaries within the grain that scientists refer to as twin boundaries. These are generally flat, crystal surfaces that mirror the crystal orientations across them. The Chinese authors created nanotwinned boundaries in copper and were analyzing the space between the boundaries when they made an interesting observation: The copper got stronger as the space between the boundaries decreased from 100 nanometers, ultimately reaching a peak of strength at 15 nanometers. However, as the spacing decreased from 15 nanometers, the metal got weaker.

"This is very puzzling," Gao said.

So Gao and Brown graduate student Xiaoyan Li dug a little further. The Brown scientists reproduced their collaborators' experiment in computer simulations involving 140 million atoms. They used a supercomputer at the National Institute for Computational Sciences in Tennessee, which allowed them to analyze the twin boundaries at the atomic scale. To their surprise, they saw an entirely new phenomenon: A highly ordered dislocation pattern controlled by nucleation had taken hold and dictated the copper's strength. The pattern was characterized by groups of atoms near the dislocation core and assembled in highly ordered, necklace-like patterns.

"They're not getting in each other's way. They're very organized," Gao said.

From the experiments and the computer modeling, the researchers theorize that at the nanoscale, dislocation nucleation can become the governing principle to determining a metal's strength or weakness. The authors presented a new equation in the Nature paper to describe the principle.

"Our work provides a concrete example of a source-controlled deformation mechanism in nanostructured materials for the first time and, as such, can be expected to have a profound impact on the field of materials science," Gao said.

Provided by Brown University