This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Sustainable and reversible 3D printing method uses minimal ingredients and steps

A new 3D printing method developed by engineers at the University of California San Diego is so simple that it uses a polymer ink and salt water solution to create solid structures. The work, published in Nature Communications, has the potential to make materials manufacturing more sustainable and environmentally friendly.

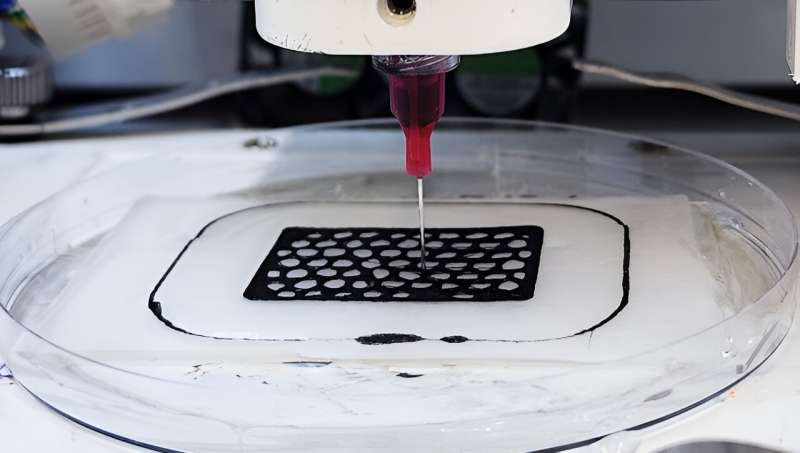

The process uses a liquid polymer solution known as poly(N-isopropylacrylamide), or PNIPAM for short. When this PNIPAM ink is extruded through a needle into a calcium chloride salt solution, it instantly solidifies as it makes contact with the salt water. Researchers used this process to print solid structures with ease.

This rapid solidification is driven by a phenomenon called the salting-out effect, where the salt ions draw water molecules out of the polymer solution due to their strong attraction to water. This removal of water causes the hydrophobic polymer chains in the PNIPAM ink to densely aggregate, creating a solid form.

"This is all done under ambient conditions, with no need for additional steps, specialized equipment, toxic chemicals, heat or pressure," said study senior author Jinhye Bae, a professor in the Aiiso Yufeng Li Family Department of Chemical and Nano Engineering at the UC San Diego Jacobs School of Engineering.

Traditional methods for solidifying polymers typically require energy-intensive steps and harsh substances. In contrast, this new process harnesses the simple interaction between PNIPAM and salt water at room temperature to achieve the same result, but without the environmental cost.

Plus, this process is reversible. The solid structures produced can be easily dissolved in fresh water, reverting to their liquid form. This allows the PNIPAM ink to be reused for further printing. "This offers a simple and environmentally friendly approach to recycling polymer materials," said Bae.

To demonstrate the versatility of their method, the researchers printed structures out of PNIPAM inks containing other materials. For example, they printed an electrical circuit using an ink made of PNIPAM mixed with carbon nanotubes, which successfully powered a light bulb. This printed circuit could also be dissolved in fresh water, showcasing the potential for creating water-soluble and recyclable electronic components.

Bae and her team envision that this simple and reversible 3D printing technique could contribute to the development of environmentally friendly polymer manufacturing technologies.

More information: Donghwan Ji et al, Sustainable 3D printing by reversible salting-out effects with aqueous salt solutions, Nature Communications (2024). DOI: 10.1038/s41467-024-48121-7

Journal information: Nature Communications

Provided by University of California - San Diego