This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

proofread

Soy biodiesel byproduct could enhance 3D printing industry

In a development that could advance the 3D printing industry, researchers at the University of Louisville have discovered a way to transform a significant waste output from soy biodiesel plants into a valuable resource.

The team, led by Dr. Jagannadh Satyavolu, has developed a process to convert matter organic non-glycerol (MONG), a byproduct of biodiesel production, into copolymers suitable for 3D printing filaments. This innovative approach not only offers an environmentally friendly solution to waste management but also presents a new avenue for value addition within the biodiesel industry.

The global demand for renewable energy sources has led to an increase in biodiesel production, resulting in a significant amount of waste byproducts such as MONG. Traditionally, MONG has been landfilled, posing environmental challenges and economic inefficiencies. However, the study presents a two-fold solution: a method to stabilize MONG for use in 3D printing and a reduction in the synthetic polymer content of natural fiber composites (NFC).

The findings are published in the Journal of Bioresources and Bioproducts.

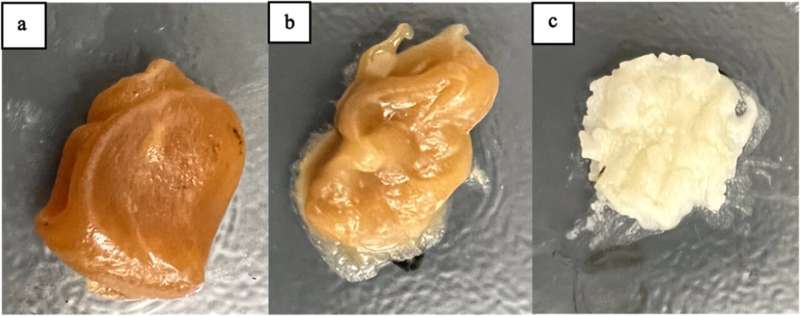

The researchers characterized soy MONG and evaluated its potential as a copolymer to produce 3D printing filaments. They focused on improving the thermal stability of MONG through two pretreatments: acid treatment and a combination of acid and peroxide.

The latter resulted in a stabilized paste with decreased soap content, increased crystallinity, and the formation of low molecular weight small chain fatty acids, making it an ideal candidate for copolymerization with thermoplastic polymers.

The study's findings indicate that acid and acid + peroxide treatments effectively split soap, reduce water solubility, and increase glycerol content in MONG. The treatments also facilitated the oxidation of fatty acids and the formation of small chain fatty acids, which are more suitable for 3D printing applications. Notably, the acid + peroxide treatment led to an increase in formic acid and oxirane concentration, suggesting successful epoxidation, a key factor for improving the thermal stability of MONG.

The researchers also conducted a comprehensive analysis of the MONG's physicochemical properties, fatty acid profile, and thermal stability. The results were promising, showing that treated MONG could be a viable alternative to synthetic polymers in NFC for 3D printing. The study concludes that the utilization of MONG in 3D printing not only adds value to a biodiesel waste product but also contributes to the development of sustainable and carbon-neutral composites.

More information: Sreesha Malayil et al, Utilization of residual fatty acids in matter organic non-glycerol from a soy biodiesel plant in filaments used for 3D printing, Journal of Bioresources and Bioproducts (2023). DOI: 10.1016/j.jobab.2023.04.001

Provided by Journal of Bioresources and Bioproducts