This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

trusted source

proofread

Researchers unveil new digital twin for precise real-time analysis of composite materials production

Researchers from IMDEA Materials Institute and the Technical University of Madrid (UPM) have developed an innovative digital twin that enables real-time analysis of composite materials manufacturing.

The breakthrough was presented in The International Journal of Advanced Manufacturing Technology in an article titled A digital twin for intelligent manufacturing of structural composites via liquid molding.

The publication is the work of IMDEA Materials researchers, Prof. Carlos González and Drs. Joaquín Fernández-León and Keayvan Keramati, along with Dr. Luis Baumela (UPM).

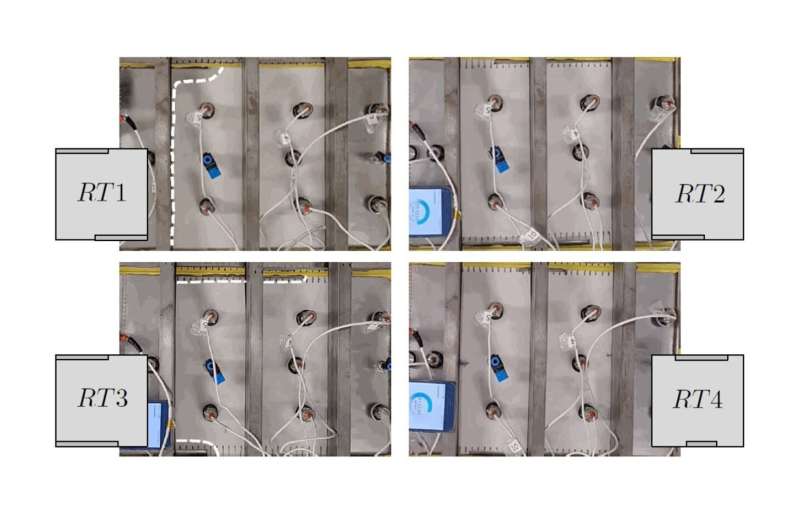

In the paper, the authors present a digital twin for analyzing the manufacturing process of structural composite materials using resin transfer molding (RTM).

"As far as I understand, this is the first digital twin designed to analyze the manufacturing process of a composite material," said co-author Prof. González, head of the Structural Composites research group at IMDEA Materials.

A digital twin is a virtual model or representation of an object, component, or system that can be updated through real-time data via sensors, either within the object itself or incorporated into the manufacturing process.

For example, an aircraft component or turbine could be equipped with various sensors designed to monitor key areas of functionality.

The data obtained by these sensors is directly incorporated into the virtual model, which can then run simulations based on the received information to identify potential material failures or performance issues.

However, what distinguishes the newly designed digital twin from similar applications is its unique focus on the composite material manufacturing process itself, rather than being limited to post-production analysis of manufactured parts.

This proactive capability allows for real-time optimizations and early fault detection, marking a significant evolution in the field of simulation-assisted digital manufacturing.

"In this publication, what we have demonstrated is a digital twin that can provide the manufacturer with a real-time picture of the material throughout the entire manufacturing process," explains Prof. González.

"This allows monitoring of how the mold is filling, the level of porosity within the material, if there are holes present, etc."

RTM represents an advanced technique within liquid composite molding (LCM), characterized by its ability to produce high-performance composite material parts with reduced void content cost-effectively.

By integrating RTM with digital twin technologies, real-time monitoring and dynamic adjustments of critical process parameters, such as injection pressure and curing time, are facilitated, significantly improving both final product quality and production efficiency.

"The next step involves the development of an advanced digital twin that enables operators to not only monitor the production process in detail, but also to intervene directly in it, applying real-time adjustments based on predictive modeling," said Dr. Fernández-León.

"This could include, for example, automatically modifying resin injection pressure or mold temperature to prevent defect formation, based on the predictive analysis of the digital twin, paving the way for highly optimized intelligent manufacturing."

More information: Joaquín Fernández-León et al, A digital twin for smart manufacturing of structural composites by liquid moulding, The International Journal of Advanced Manufacturing Technology (2024). DOI: 10.1007/s00170-023-12637-x

Provided by IMDEA Materials