This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

trusted source

proofread

Carbon-based supports for electrocatalysis under industrially relevant conditions

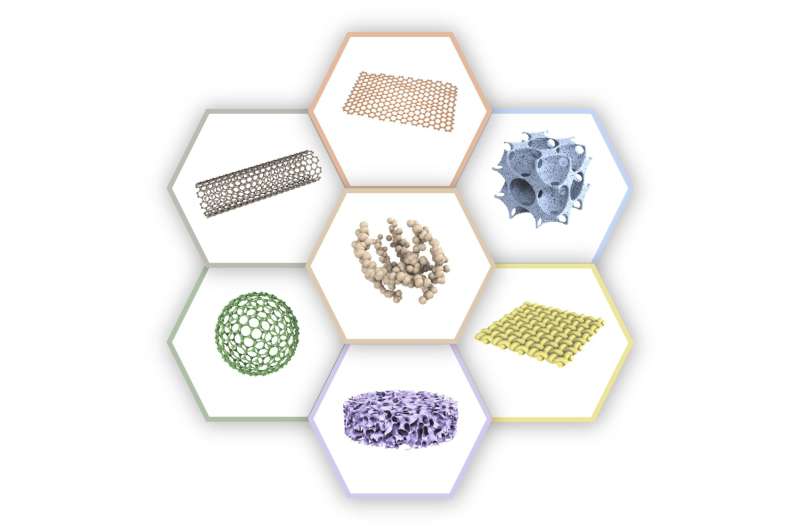

Carbon materials, due to their appropriate physicochemical characteristics such as high surface area, adjustable pore structure, variable morphology, and multifunctional surface properties based on chemical modifications, low cost, and ease of preparation from various precursors, are ideal carrier materials for functional metal components.

Particularly in electrochemical systems (such as proton exchange membrane fuel cells, PEMFC, and proton exchange membrane water electrolysis, PEMWE), carbon materials play a vital role because they can serve as conductive carriers for active metal components.

However, in the rapidly growing literature in the field of electrocatalysis, most studies typically focus on functional metal or metal oxide components supported by commercial carbon. The role of carbon materials as supports and their impact on catalytic performance has not received sufficient attention, warranting more research efforts from both academia and industry.

This review, published in the journal Science China Chemistry, was led by Prof. Wei Lin (SINOPEC Research Institute of Petroleum Processing) and Prof. Lichen Liu (Department of Chemistry, Tsinghua University).

Prof. Wei Lin and Prof. Lichen Liu attempted to approach the topic from an industrial perspective, discussing key parameters that can be directly measured or studied in experiments to reveal the synthesis-structure-performance relationship.

The paper systematically introduces and explains the application of carbon carrier materials in the electrochemical field under industrially relevant conditions and the existing challenges and future breakthrough directions from six aspects: electrochemical conductivity, chemical composition, stability under industrial conditions, mass transfer, bulk synthesis, and in-depth understanding.

Finally, based on their knowledge and experience accumulated in industrial R&D activities, the authors propose the following critical standards that carbon supports in practical electrocatalytic devices need to meet: (1) specific surface area > 60 m²/g; (2) electrical resistivity <2.5 Ω·m; (3) primary carbon particle size < 50 nm; (4) recyclability over 5000 cycles (at 1.0-1.5V); (5) cost below $4000/ton.

Specifically, the authors also suggest a primary carbon particle size < 50 nm, as smaller particles can improve conductivity and viscosity, enhance weather resistance, provide better reinforcement, and increase tensile strength and abrasion resistance. Additionally, smaller particle size is correlated with a greater specific surface area, facilitating dense platinum loading and the construction of thin catalyst layers.

These key indicators can serve as guiding parameters for the development of advanced carbon carriers for PEMFC and PEMWE devices. The first author of the paper is Dr. Xue Yang from Sinopec Research Institute of Petroleum Processing.

More information: Xue Yang et al, Carbon-based supports for the electrocatalysis under industrially relevant conditions, Science China Chemistry (2023). DOI: 10.1007/s11426-023-1887-7

Provided by Science China Press