This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Light guide plate based on perovskite nanocomposites

The fact that nanoparticle and polymer hybrid materials can often combine the advantages of each has been demonstrated in several fields. Embedding PNCs into polymer is an effective strategy to enhance the PNCs stability and polymer can endow the PNCs with other positive effects based on different structure and functional groups.

The uniform distribution of PNCs in polymer matrix is critical to the properties of the nanocomposites and the aggregation of PNCs induced by high surface energy has a severe influence on the performance of related applications. As such, the loading fraction is limited owing to the phase separation between PNCs and polymer.

Chemical interaction between PNCs and polymer is necessary to suppress the phase separation. Meanwhile, most of the fabrication methods of PNCs/polymer nanocomposites are spin coating, swelling-shrinking and electrospinning based on the in-situ synthesis of PNCs in polymer matrix and physical mixing, but extremely few works can achieve the fabrication of PNCs/polymer nanocomposites by bulk polymerization.

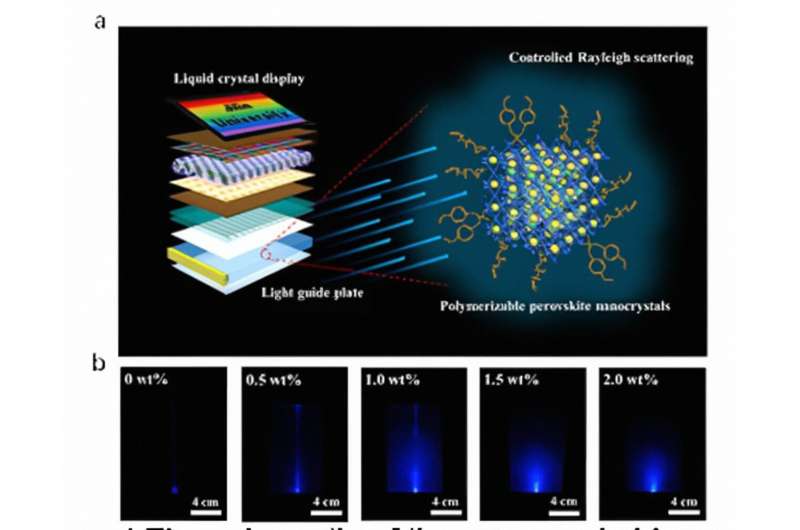

In a new paper published in Light: Science & Applications, a team of scientists, led by Professor Bai Yang from State Key Laboratory of Supramolecular Structure and Materials, College of Chemistry, Jilin University, China, and co-workers have adopted a two-type ligand strategy to fabricate PNCs/polystyrene (PS) nanocomposites, where the undec-10-en-1-amine help PNCs disperse in styrene and the synthetic bis[(4-ethenylphenyl)methyl]dimethylammonium chloride works as polymerizable capping ligands to endow the PNCs with polymerization activity.

The bulk CsPbCl3 PNCs/PS nanocomposites can still maintain high transparency even at the doping content up to 5 wt%.

The high transparency can be ascribed to the Rayleigh scattering as the PNCs distribute uniformly without obvious aggregation. Based on this behavior, the scientists further exploit the potential of the PNCs/PS nanocomposites to serve as LGP and study the principle of this new type of LGP.

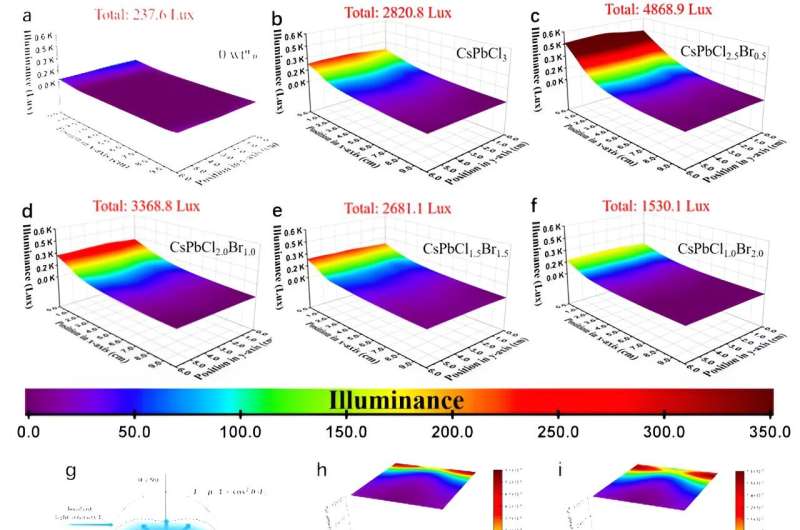

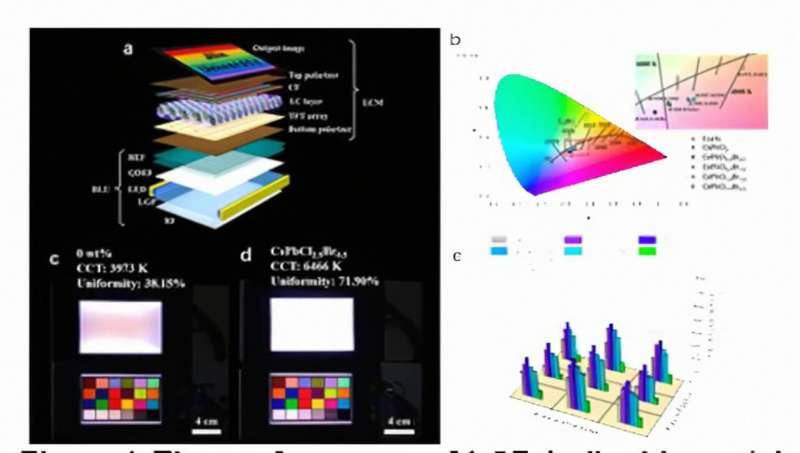

Through the facile composition adjustment of CsPbClxBr3-x (1≤x≤3) PNCs, the Rayleigh scattering behavior can be adjusted and the scientists systematically study the influence of PNCs composition on the performance of LGP by calculating the volume scattering coefficient and optical radiation efficiency of the nanocomposites.

Furthermore, this new type of LGP is compatible with advanced liquid crystal display (LCD) technology. Both surface illuminance and uniformity show obvious improvement. For 5.0-inch LGP, the best performing LGP doping with 1 wt% CsPbCl2.5Br0.5 PNCs exhibits about 20.5 times higher illuminance and 1.8 times higher uniformity in display than the control.

This kind of LGP has potential in LCD-related applications and will draw much attention in LGP-related fields, especially as a base material to combine with the advanced LGP processing technologies such as the micro-optical pattern on the bottom or the adoption of the wedge-shaped plates.

More information: Chongming Liu et al, Bulk CsPbClxBr3-x (1 ≤ x ≤ 3) perovskite nanocrystals/polystyrene nanocomposites with controlled Rayleigh scattering for light guide plate, Light: Science & Applications (2023). DOI: 10.1038/s41377-023-01306-z

Journal information: Light: Science & Applications

Provided by Chinese Academy of Sciences