This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Dual-laser approach could lower cost of high-resolution 3D printing

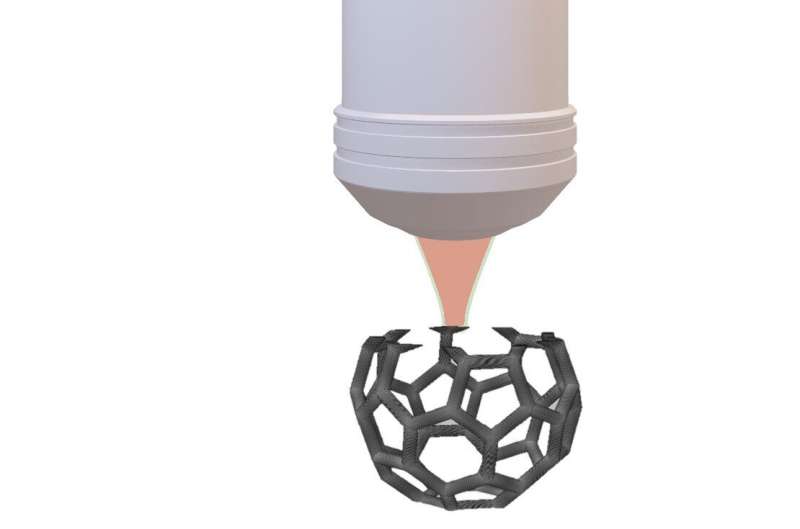

Researchers have developed a new two-photon polymerization technique that uses two lasers to 3D print complex high-resolution structures. The advance could make this 3D printing process less expensive, helping it find wider use in a variety of applications.

Two-photon polymerization is an advanced additive manufacturing technique that traditionally uses femtosecond lasers to polymerize materials in a precise, 3D manner. Although this process works well for making high-resolution microstructures, it isn't widely used in manufacturing because femtosecond lasers are expensive and increase the cost of printing parts.

"We combined a relatively low-cost laser emitting visible light with a femtosecond laser emitting infrared pulses to reduce the power requirement of the femtosecond laser," said research team leader Xianfan Xu from Purdue University. "In this way, with a given femtosecond laser power, the printing throughput can be increased, leading to a lower cost for printing individual parts."

In the journal Optics Express, the researchers show that the two-laser approach reduces the femtosecond laser 3D printing power needed by as much as 50% compared to using a femtosecond laser alone.

"3D printing with high resolution has many applications, including 3D electronics devices, micro-robots for the biomedical field and 3D structures or scaffolds for tissue engineering," said Xu. "Our novel, 3D printing approach can be readily implemented in many existing femtosecond laser 3D printing systems."

Finding the right laser balance

The new work is part of the research team's effort to continuously improve the printing speed and reduce the printing cost for two-photon polymerization, which uses the phenomenon of two-photo absorption to precisely cure, or solidify, a photosensitive material.

"In a conventional two-photon polymerization printing process, the femtosecond laser is first used to initiate a photochemical process that reduces the inhibition species in the material before printing starts," said Xu. "We used a low-cost laser for this purpose instead."

The new approach combines single-photon absorption from a 532 nm nanosecond laser with two-photon absorption from an 800-nm femtosecond laser. For this to work, the researchers had to find the right balance between the printing and inhibition caused by the two lasers.

They did this by creating a new mathematical model to help them understand the photochemical processes involved and to compute the combined effect of two-photon and single-photon excitation processes. They also used the model to identify the dominant processes controlling how much the femtosecond laser's power could be reduced while still achieving desirable printing results.

Printing detailed structures

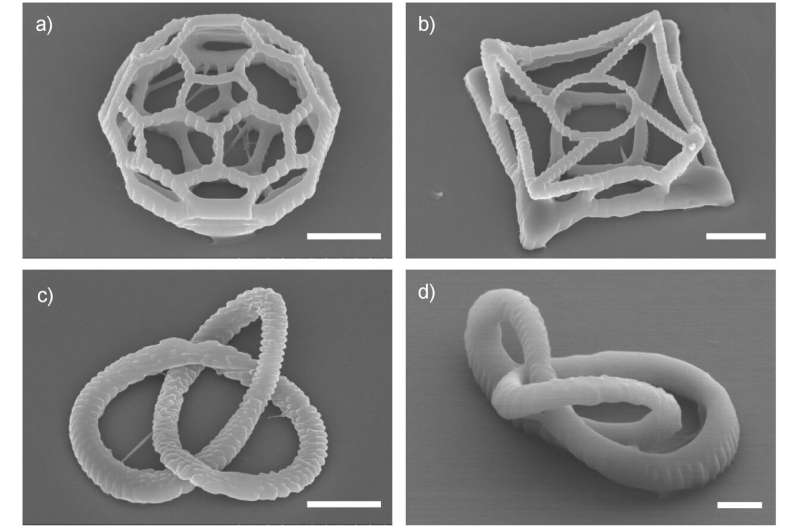

After fine-tuning the new approach, they used it to print various 2D and 3D structures using reduced femtosecond laser power. These included detailed woodpiles measuring just 25 × 25 × 10 μm, as well as a micron-scale buckyball, chiral structure and trefoil knot. Experimental results showed that the new method reduced the power required from the femtosecond laser by up to 80% for 2D structures and up to around 50% for 3D structures.

"This new printing approach could impact manufacturing technologies, influencing the development of devices across consumer electronics and health care sectors both now and in the future," said Xu. The researchers are now working to further improve the printing speed and reduce the cost of 3D printing.

More information: Anwarul Islam Akash et al, Two-color 3D printing for reduction in femtosecond laser printing power, Optics Express (2024). DOI: 10.1364/OE.525826

Journal information: Optics Express

Provided by Optica