This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

proofread

Gaining more control over the fabrication of surface micro/nano structures using ultrafast lasers

Surface functionalization via micro/nano structuring is not only a thriving research area inspired by bionics but also of great importance for various practical applications. The key to achieving various surface functions is the fabrication of surface micro/nano structures with controlled dimensions, hierarchies, and compositions, which is driving the continuous progress of micro/nano fabrication techniques.

Researchers from the Laser Materials Processing Research Center at the School of Materials Science and Engineering of Tsinghua University, China, have spent years developing laser-enabled fabrication techniques for preparing surface micro/nano structures and exploring their functional applications.

The work entitled "Localized in-situ deposition: a new dimension to control in fabricating surface micro/nano structures via ultrafast laser ablation" was published in Frontiers of Optoelectronics.

The researchers have established the capabilities to separately and finely control the micro- and nanoscale features as well as control how they are combined to form different types of multi-level structures, say the researchers. The functions and applications they have studied include extreme wettability, anti-icing, broadband light absorption, structural colors, solar water evaporation, thermal interface management, tribological properties, surface-enhanced Raman spectroscopy, and photoelectrocatalysis for energy applications, etc.

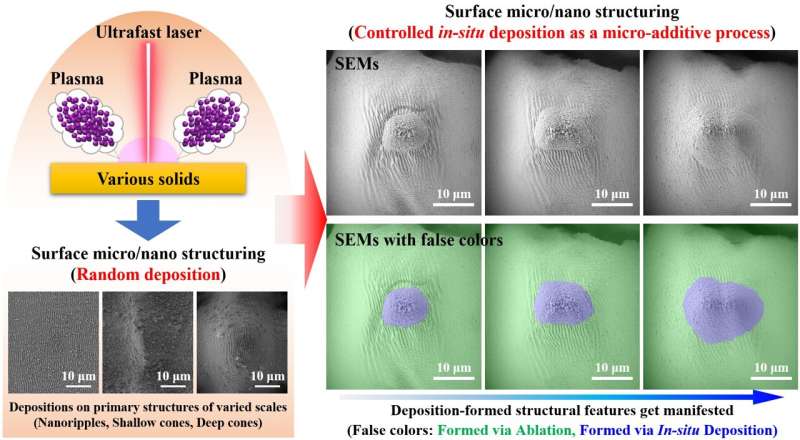

Gaining more control over the structure fabrication using ultrafast lasers and developing more flexible fabrication approaches is one of their continuous research focuses. In addition to controlling the ultrafast laser ablation process, they recently demonstrated that the in-situ deposition of particles following ultrafast laser ablation of solid surfaces could also be controlled and used as a localized micro-additive process to pile up hierarchical surface structures.

The plasma plume formation is a universal phenomenon that occurs during pulsed laser ablation of solids. The products (nanoparticles) from the plasma plumes can be collected for usage by external liquids (in the case of laser ablation in liquids) or substrates (in the case of pulsed laser deposition).

In contrast, some of the nanoparticles from the plasma plumes in-situ deposit back to the irradiated surfaces during ultrafast laser surface structuring. For specific applications, the in-situ deposited structural features play a significant role in enhancing surface properties like light absorption, sensibility, and energy conversion.

However, whether and how the in-situ deposition process can be controlled remains an open question. Their recent studies showed a capability of controlling the in-situ deposition process, e.g., to build fort-like structures on top of micro cone arrays rather than just producing randomly distributed nanoparticles. The revealed laser-matter interaction mechanism can motivate future research interests to explore new possibilities in the fabrication of functional surface micro/nano structures using ultrafast lasers.

More information: Peixun Fan et al, Localized in-situ deposition: a new dimension to control in fabricating surface micro/nano structures via ultrafast laser ablation, Frontiers of Optoelectronics (2023). DOI: 10.1007/s12200-023-00092-1

Provided by Higher Education Press