This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

proofread

Review explores biofabrication strategies with single-cell resolution

The recent advances in biofabrication with extremely high resolution (e.g. at the single-cell level) have greatly enhanced the capacity of biofabrication and opened new avenues for tissue engineering.

Scientists from Tsinghua University have provided a perspective to review the advances in the biofabrication of engineering living systems with single-cell resolution.

The research interests of Dr. Ouyang's team include the design, fabrication, and application of complex biomaterial and cellular systems, with a central focus on the development of 3D bioprinting and advanced biofabrication technologies for tissue engineering and regenerative medicine. Since cells are the basic units of the living systems, they believe the engineering living systems with single-cell features is important to recapitulate the microenvironment in the native tissues.

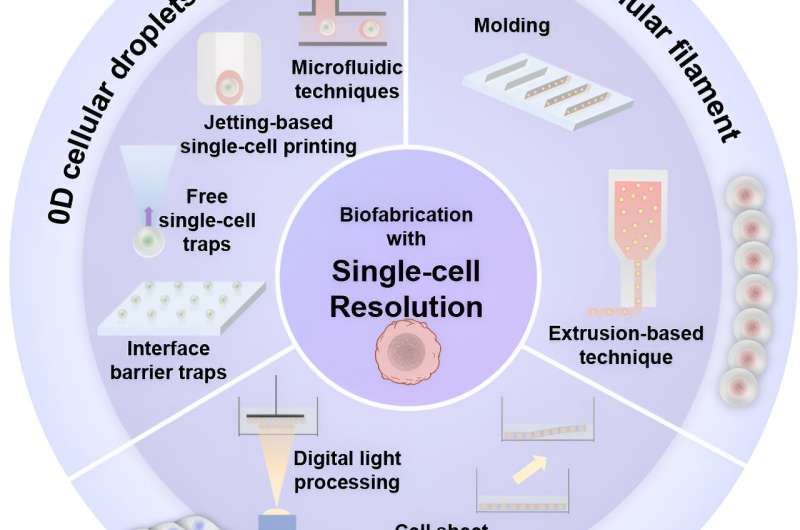

This review, published in International Journal of Extreme Manufacturing, provides an overview of the biofabrication methods based on the modular assembly of cellular building blocks with single-cell features in different dimensions and provides an informative introduction to the most recent advances.

"Heterogeneity with single-cell resolution is a common phenomenon within natural living systems, so the techniques to manipulate the single cells to reconstruct the engineering living systems are valuable. But several factors such as the mechanical strength of the products, and fabrication efficiency should be well considered, and it is important to select the proper single-cell building blocks for a specific use," said Dr. Liiang Ouyang, an associate professor in Mechanical Engineering at Tsinghua University and the senior author on the review.

"In principle, the size of building blocks would determine the minimum feature of the structure and it takes longer to assemble a large-scale cellular structure with smaller building blocks. To simultaneously achieve high resolution and fabrication efficiency, we suggest a modular assembly strategy, enabling co-assembly of building blocks with different sizes to form desired heterostructures," said Dezhi Zhou, a Ph.D. student and the first author of the paper.

Each type of tissue/organ possesses its unique structure to realize its function. For example, pancreatic islets are composed of at least five types of cells, forming special junctions within a dimension of several cells, to maintain blood glucose homeostasis via cell–cell interaction; Skeletal muscle is an anisotropic tissue containing bundled muscle fascicles encased by the epimysium, and the muscle fascicles exhibit the normal function by order transition between relaxation and contraction.

Alveolus is another example, which presents multi-layer walls surrounded by a network of capillaries for gas exchange. The unique multi-layer structure with a few micrometers of thickness can provide a large surface (100–140 m2) for effective gas exchange. Therefore, it is fundamental to rebuild these topological structures to ensure the function of the engineering living systems.

"Just like playing the LEGO, we select the proper blocks and put them together to make what we want," said Zhou. That is enormously helpful to build up a complex structure to mimic the natural living systems. "But to scientists, how to create the proper living building blocks and controllably assemble them is an enduring challenge," said Dr. Ouyang.

Based on the 'dispersion-deposition' principle, complex living systems can be regarded as an assembly of various discrete elements including single-cell-feature building blocks and cell-population/biomaterial building blocks. Then the counterparts of each discrete element could be generated and placed together to rebuild the desired object. "We believe the combination of these two building blocks can contribute to engineering complex tissues with both physicochemical and biological features," said Zhou.

More information: Dezhi Zhou et al, Biofabrication strategies with single-cell resolution: a review, International Journal of Extreme Manufacturing (2023). DOI: 10.1088/2631-7990/ace863

Provided by International Journal of Extreme Manufacturing