This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

From 2D to 3D: MXene's path to revolutionizing energy storage and more

With a slew of impressive properties, transition metal carbides, generally referred to as MXenes, are exciting nanomaterials being explored in the energy storage sector. MXenes are two-dimensional materials that consist of flakes as thin as a few nanometers.

Their outstanding mechanical strength, ultrahigh surface-to-volume ratio, and superior electrochemical stability make them promising candidates as supercapacitors—that is, as long as they can be arranged in 3D architectures where there is a sufficient volume of nanomaterials and their large surfaces are available for reactions.

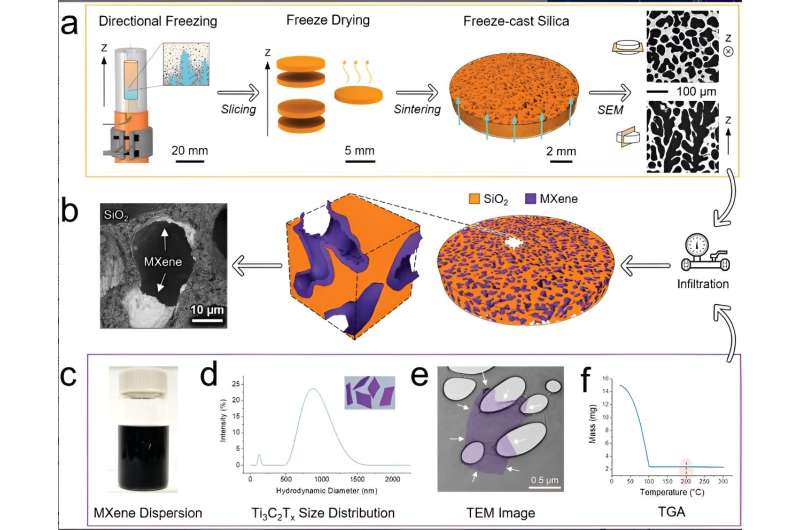

During processing, MXenes tend to restack, compromising accessibility and impeding the performance of individual flakes, thereby diminishing some of their significant advantages. To circumvent this obstacle, Rahul Panat and Burak Ozdoganlar, along with Ph.D. candidate Mert Arslanoglu, from the Mechanical Engineering Department at Carnegie Mellon University, have developed an entirely new material system that arranges 2D MXene nanosheets into a 3D structure.

This is accomplished by infiltrating MXene into a porous ceramic scaffold, or backbone. The ceramic backbone is fabricated using the freeze-casting technique, which produces open-pore structures with controlled pore dimensions and pore directionality.

The study is published in the journal Advanced Materials.

"We are able to infiltrate MXene flakes dispersed in a solvent into a freeze-cast porous ceramic structure," explained Panat, a professor of mechanical engineering. "As the system dries, the 2D MXene flakes uniformly coat the internal surfaces of the interconnected pores of the ceramic without losing any essential attributes."

As described in their earlier publication, the solvent used in their freeze-casting approach is a chemical called camphene, which produces tree-like dendritic structures when frozen. Other types of pore distributions can also be obtained by using different solvents.

To test the samples, the team constructed "sandwich-type" two-electrode supercapacitors and connected them to an LED light with an operating voltage of 2.5V. The supercapacitors successfully powered the light with higher power density and energy density values than previously obtained for any MXene-based supercapacitors.

"Not only have we demonstrated an exceptional way to utilize MXene, we've done so in a way that is reproducible and scalable," said Ozdoganlar, also a professor of mechanical engineering. "Our new material system can be mass-manufactured at desired dimensions to be used in commercial devices. We believe this can have a tremendous impact on energy storage devices, and thus, on applications such as electric vehicles."

With outstanding experimental results and electrical conductivity that can be finely tuned by controlling the MXene concentration and the porosity of the backbone, this material system has far-reaching potential for batteries, fuel cells, decarbonization systems, and catalytic devices. We may even see an MXene supercapacitor power our electric vehicles one day.

"Our approach can be applied to other nano-scale materials, like graphene, and the backbone can be built from materials beyond ceramics, including polymers and metals," Panat said. "This structure could enable a wide range of emerging and novel technology applications."

More information: Mert Arslanoglu et al, 3D Assembly of MXene Networks using a Ceramic Backbone with Controlled Porosity, Advanced Materials (2023). DOI: 10.1002/adma.202304757

Journal information: Advanced Materials