October 7, 2023 feature

This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Free-space nanoprinting beyond optical limits to create 4D functional structures

Two-photon polymerization is a potential method for nanofabrication to integrate nanomaterials based on femtosecond laser-based methods. Challenges in the field of 3D nanoprinting include slow layer-by-layer printing and limited material options as a result of laser-matter interactions.

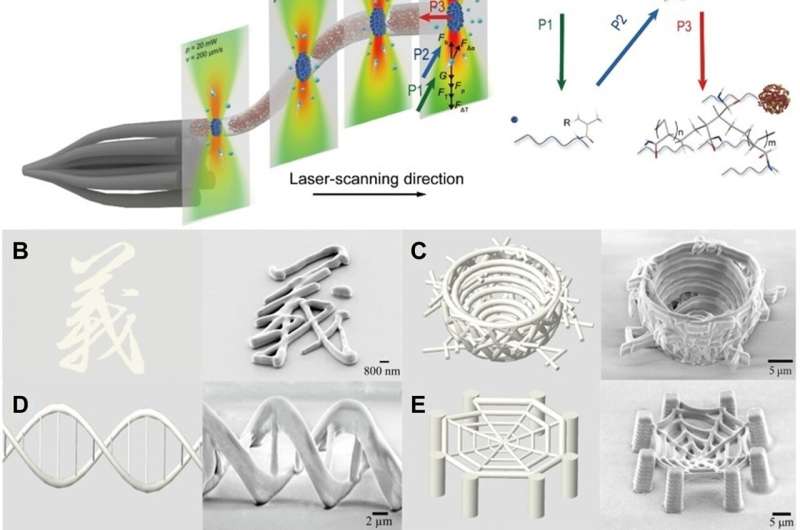

In a new report now on Science Advances, Chenqi Yi and a team of scientists in Technology Sciences, Medicine, and Industrial Engineering at the Wuhan University China and the Purdue University U.S., showed a new 3D nanoprinting approach known as free-space nanoprinting by using an optical force brush.

This concept allowed them to develop precise and spatial writing paths beyond optical limits to form 4D functional structures. The method facilitated the rapid aggregation and solidification of radicals to facilitate polymerization with increased sensitivity to laser energy, to provide high accuracy, free-space painting much like Chinese brush painting on paper.

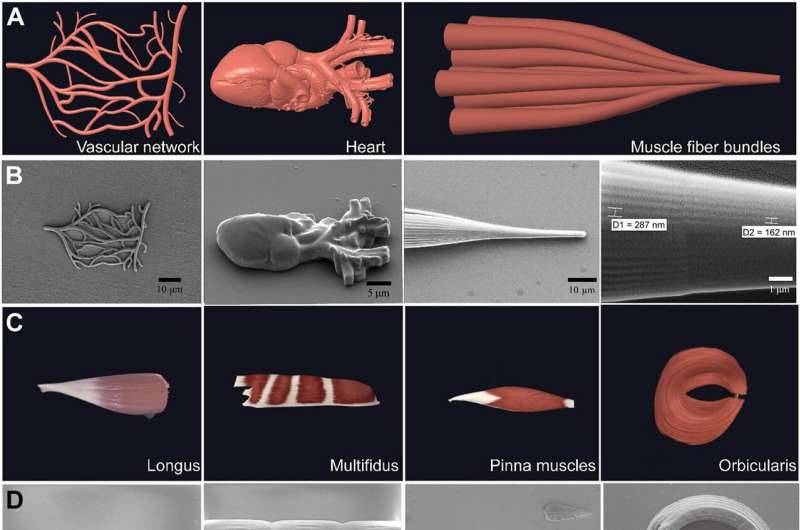

Using the method, they increased the printing speed to successfully print a variety of bionic muscle models derived from 4D nanostructures with tunable mechanical properties in response to electrical signals with excellent biocompatibility.

Device engineering

Nanodevices and nanostructures can be engineered at high resolution and speed to form next-generation products. The semiconductor industry can use lithography, deposition and etching to create 3D structures from a variety of materials, although the high processing cost and limited selection of materials can affect flexible fabrication of 3D structures of functional materials.

Materials scientists have used two-photon polymerization-based femtosecond laser direct writing to create complex 3D nanostructures using micro/nanopolymers to form photonic quasicrystals, metamaterials, and nanoarchitectures.

However, this method is still limited by a slow speed of printing, stairwise surface textures and limited photocurable materials. In this work, Yi et al. examined free-space laser writing to analyze how it yields photochemical forces to accomplish optical force brush-based nanopainting.

Free-space painting with a femtosecond laser

When timescales reach the femtosecond, molecules can absorb the photon for excitation into an electronically higher state with a repulsive potential energy surface, to generate free radicals.

Scientists can use multiphoton absorption mechanisms to absorb ultrashort pulse photon energy in molecules and activate electron transition between the ground and excited state. Yi and colleagues irradiated active radicals with a femtosecond laser for the optical forces to rapidly aggregate them and synthesize into macromolecules to quickly complete solidification without post-processing, while minimizing thermal motion of the solvent molecules.

The researchers developed a hydrogel-based ink as a photoswitch activated upon femtosecond laser writing through two-photon absorption, where radicals in the gel absorbed photon energy from the femtosecond laser. While free radicals formed binding energy in the molecules, the team connected the long-chain molecules to different functional groups for a variety of applications.

The printable hydrogel-based ink offered highly biocompatible, elastic, and flexible conditions for multiple applications of free-space printable nanostructures in biomedicine.

Mechanism-of-action

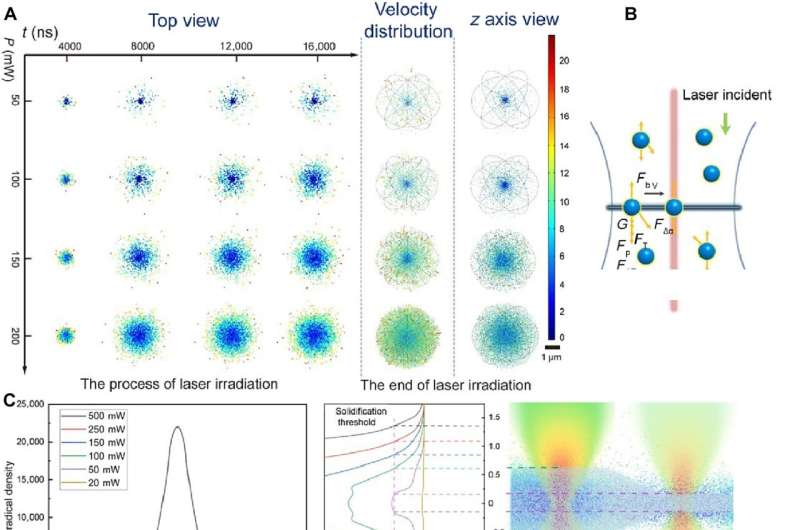

The laser beam moved freely in solution much like a pen in space and involved three steps: activation, aggregation, and solidification of free radicals. The scientists cultured the polymerization rates for two photon polymerization and optical force brush separately with a multiphysics model.

The approach greatly improved the efficiency of the writing structure through a layer-by-layer, line-by-line printing method, where the number of layers directly correlated with the thickness resolution. The method also facilitated greatly improved 3D nanostructure writing efficiency and accuracy. They refined the experimental results to show how the optical force applied to the free radicals were directly related to the number of pulses, the intensity of the laser-field and its absorption coefficient.

As the femtosecond laser irradiated the material, the kinetic energy from the photons were exchanged with the active free radicals to move by the optical force, eventually resulting in sharp and high-resolution 3D nanoprinting. The team studied the fundamental mechanisms underlying these processes through numerical simulations via multiphysics simulations to examine the motion and composite process of the radicals.

Engineering a nested muscle system

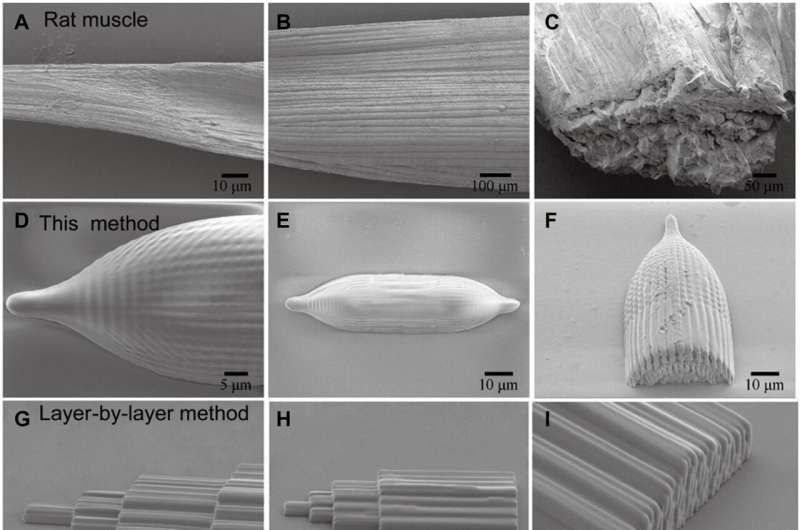

This method allowed Yi and colleagues to print muscle, belly, and tendon tissues composed of multilayered nesting of fibers and fiber bundles that are difficult to print via traditional 3D printing methods. The team printed the muscle's internal and external shape, while activating its movement via electrical stimulation with a functional hydrogel-based ink. This results in the initial instance of simultaneously achieving both structural and functional bionic nanoprinting.

The scientists demonstrated the structure of rat hamstring's tendon and belly printed by optical force brush and layer-by-layer method. The methods showed the potential to print multilayer structures in 3D space, while the muscle fiber thickness turned thin to thick to impart a variety of functionalities.

The researchers showed the possibility of completely implanting the micro- and nanostructures into an organism to realize functional and structural biostructures at this scale. This free-space printing method through the optical force brush technique opens possibilities to apply multifunctional micro and nanostructures in biology.

Outlook

In this way Chenqi Yi and colleagues used optical force brush as a method that integrated femtosecond laser paintbrush to print functional structures with true 3D freedom. The optical force brush has unique capabilities with an underlying process of optical force enabled nanopainting, to facilitate an ultrahigh solidification rate, low solidification threshold, and high sensitivity to laser to precisely regulate the printing process. The sensitivity allowed them to accurately regulate and create intricate structures with fine details.

This resulted in true 3D printing freedom for continuous printing and seamless transitions between different planes. The work further explored the mechanisms of optical forces for nanoprinting in free space during optical force brush use. This included interactions of the femtosecond laser with free radicals in the hydrogel ink photoswitch; a mechanism also explored through numerical simulations.

The research emphasized the capacity of the optical force brush to develop bionic functional structures and pave the way for additional studies in tissue engineering and regenerative medicine with breakthrough properties.

More information: Yi C. et al, Optical force brush enabled free-space painting of 4D functional structures, Science Advances (2023). DOI: 10.1126/sciadv.adg0300

Ergin T. et al. Three-dimensional invisibility cloak at optical wavelengths, Science (2023). DOI: 10.1126/science.1186351

Journal information: Science , Science Advances

© 2023 Science X Network