This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

3D-printed hairs: Professor developing tiny sensors to detect flow and environmental changes

Eyelashes and brows catch dust and debris from entering eyes. The same idea goes for tiny nose and ear hairs. At a more microscopic level, the tiny hair-like cilia that line human cells help detect subtle environmental changes and can boost a person's senses.

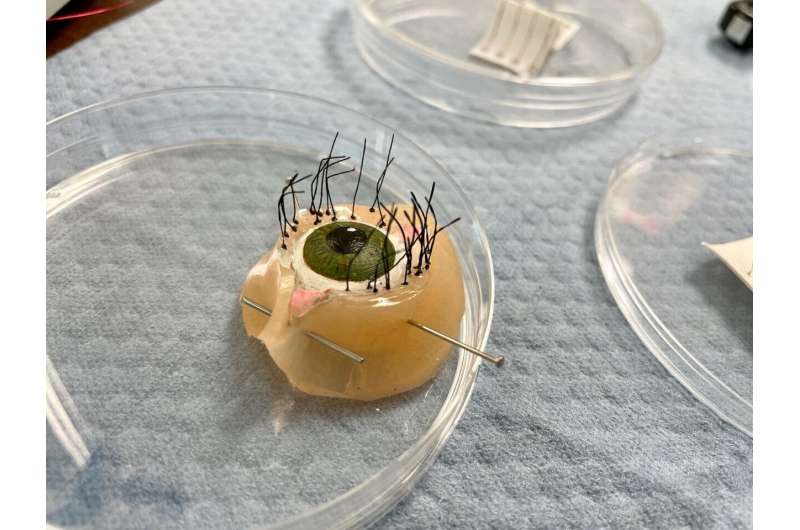

These are the concepts that nanoscience and nanotechnology doctoral candidate Phillip Glass and advisor Daeha Joung, Ph.D., are pursuing with their 3D-printed cilia sensors at the Virginia Commonwealth University Department of Physics in the College of Humanities and Sciences. The two are exploring the field of mechanosensing, a biological term for the methods the body uses to collect external stimuli and send it to the brain—resulting in senses like touch, hearing, movement and pain. Mechanoreceptors are cells or organs that perform the sensing.

Now they're bringing the human concept to machines and robots.

"There's all kinds of places where we could use these," said Glass while showing off the laboratory's tiny, 3D-printed sensors that look like human hairs. Existing mechanosensing technologies, Glass said, can sense sustained pressures, quick pressures and temperature changes. "But one area that hasn't been as explored is the concept of 'sliding' force—for example, that feeling you get on your skin as you remove or put on clothing," Glass said.

The use of the team's receptors remains to be seen, but Glass and Joung—an assistant professor of experimental biophysics and nanoscience—point to a number of applications in industrial, environmental and biomedical fields. They outline their findings and the physics behind their IP in a July 2023 article that the pair and their VCU team published in Advanced Science, "3D-Printed Artificial Cilia Arrays: A Versatile Tool for Customizable Mechanosensing."

Uses, they say, could include minimally-invasive surgical robots equipped with cilia mechanoreceptors to better detect minute changes in pressure or temperature, industrial machines that can measure air or water flow, a robot that can read braille, or debris detection on a highly sensitive camera lens.

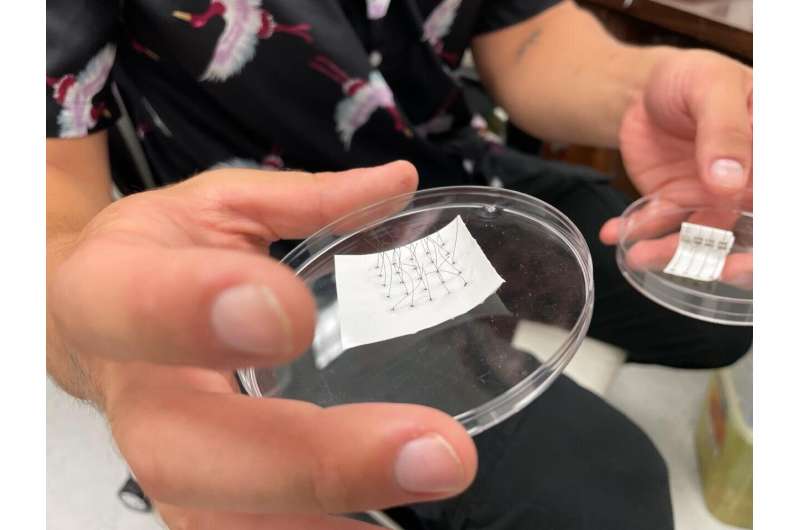

In the case of reading braille, cilia were aligned in a brush-like structure and attached to a robot, which was dragged across a surface with braille dots on it. Data collected from the robot accurately mapped out the shape of the braille.

"Phillip and Dr. Joung's technology is really a platform that can be used in a number of industries, from prosthetics—think, making a person's prosthetic fingers or toes more sensitive to touch—to manufacturing that requires dynamic fluids," said Brent Fagg, senior licensing manager at VCU TechTransfer and Ventures. "The challenge now is to find the right early-stage partners to develop a market-ready application, and we're talking to a number of groups that have interest."

Measuring air and water flow rates is a critical opportunity, Glass said, which is an important factor in a broad number of markets from factories to hospitals. "So many applications and industries need to control, measure and even predict the rate of air or water," he said.

Glass's cilia sensors are formed on a customized 3D printer using a material called polycaprolactone (PCL) mixed with graphene (a highly conductive super nanomaterial) and a solvent that dries on contact with air. 3D printing also gives Glass flexibility to print cilia of different sizes "just by changing a few lines of code."

"One of the huge selling points of our technology is that we can print different-sized hairs, which can feel the stimulus differently," Glass said. "Really long hairs bend more easily than short ones, so while other types of airflow sensors can only detect a single range of flow, we can print our cilia in different sizes and spacings and make them more sensitive to a wide range of stimuli."

For Joung, the sensors underpin the importance of physics as a foundational element in real-world applications. "The greatest strength of physics is that it is the foundation for any new application, whether it is a biomedical device or engineering process," Joung said. "Phillip has really taken a different approach, using uniqueness and creativity to dream up a new idea with real-world potential."

More information: Phillip Glass et al, 3D‐Printed Artificial Cilia Arrays: A Versatile Tool for Customizable Mechanosensing, Advanced Science (2023). DOI: 10.1002/advs.202303164

Journal information: Advanced Science

Provided by Virginia Commonwealth University