This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

A self-powered sensor made from plants

The story of Qi Chen's research is full of serendipity. In the first year of her Ph.D., she was hanging out with friends at the University's Zernike campus, discussing the topics of their research. Chen told them she was going to study foam-like materials. A friend was casually peeling the stem of a grass-like plant, thereby revealing its insides that appeared to have an open and airy structure. He suggested jokingly that Chen might want to study it. She put it in her backpack and then forgot all about it.

Nearly two years later, Chen found the plant again in her backpack. She had been trying to induce electricity from bacteria, using foamy materials as an environment for them to live in. The results weren't promising, so she decided to have a closer look at this grass-like plant: a common wetland weed called soft rush (Juncus effusus L.).

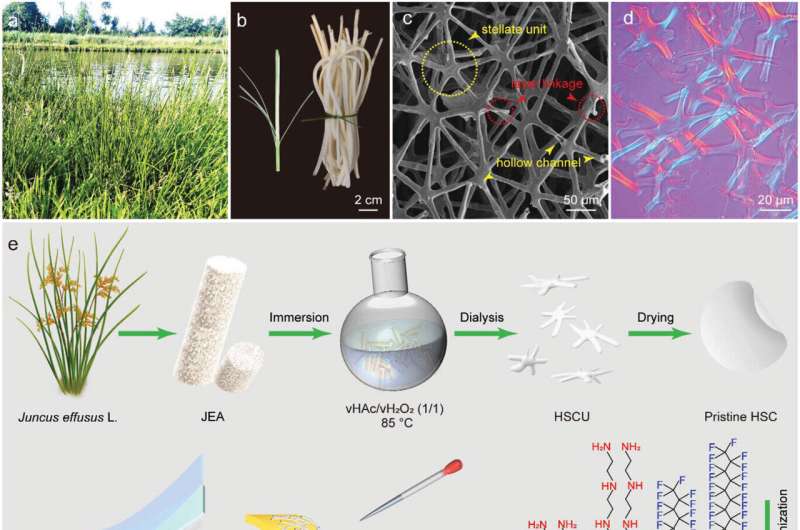

Tiny snowflakes

"The structure of the soft rush stem consists of layers of interconnected stars, a bit like tiny snowflakes," Chen explains. These layers are stacked on top of each other, creating a structure that allows a lot of air to flow through. Chen says, "My samples were ultra-lightweight. Once, I left the samples uncovered and as I opened the lab door, the samples were blown away. It looked like it had snowed in the hallway."

The insides of many aquatic or wetland plants consist of such an open structure, called aerenchyma. "The plant needs this open structure to breathe," Chen says, "because with their roots in a wet environment, they need to take oxygen from the air and transport it through the stem." As it turns out, this material is also a great alternative resource for natural plant-based foams.

A tiny device to put in your shoe

The unique shape of the little snowflakes in the soft rush stem were also perfect for building a nanogenerator: a tiny device that produces an electric charge, which can be used as a sensor or as an energy source. Such a nanogenerator can help make the current trend of ever smaller wearable devices more sustainable, replacing batteries that ultimately end up in electronic waste.

Together with colleagues Wenjian Li and Feng Yan, Chen built a nanogenerator the size of a postage stamp, about one millimeter thick. It works as a motion sensor, co-author Dina Maniar explains, "You can put it in your shoe and when you walk, jump, or run, it releases a distinct signal that we can recognize."

This tiny device builds on the same phenomenon that gives you a shock when you touch a doorknob after walking on a carpet: the so-called triboelectric effect. It consists of two small layers with rough surfaces. The two layers are kept apart by a separator, but when pressed there is friction between the layers, which creates an electric charge—just like the electric charge that builds up when you shuffle your feet on a carpet. Maniar says, "This enables us to convert movement into electrical signals."

The tiny snowflakes from the soft rush plant create a rough, foamy surface with many pores on the layers of the nanogenerator: perfect for optimal friction between the layers, while keeping it very lightweight. This was once again a serendipitous finding: Chen dropped some of her dissolved plant material on aluminum foil and failed to clean it up. The water evaporated, leaving a thin film with the rough surface of tiny snowflakes.

We can really call it sustainable

Researchers have been trying to produce foam-like materials based on cellulose from plants for years. "Usually, a lot of resources go into extracting cellulose, breaking down the structure as it was," Professor of Applied Chemistry and co-author Katja Loos explains. "Then, a lot of resources go into producing the desired structure for new materials."

Chen was able to retain the building blocks—the little 'snowflakes'—of the soft rush insides, by peeling the stem and dissolving it in a simple mixture. "So, we can really call it sustainable," says Chen. Little energy and no oil-based fossil materials went into this process. Chen is currently working on other applications. She wants to use the soft rush snowflakes as part of a battery, and for clearing up pollutants in water.

Unfortunately, the local municipality has recently removed a lot of the soft rush growth, Chen discovered. She shrugs. "Now I just have to cycle a bit further to get it." She smiles, "In our lab, it's not a weed; it's a valuable resource."

The work is published in the journals Advanced Functional Materials and Cellulose.

More information: Qi Chen et al, Lightweight Triboelectric Nanogenerators Based on Hollow Stellate Cellulose Films Derived from Juncus effusus L. Aerenchyma, Advanced Functional Materials (2023). DOI: 10.1002/adfm.202304801

Qi Chen et al, Aerenchyma tissue of Juncus effusus L.: a novel resource for sustainable natural cellulose foams, Cellulose (2023). DOI: 10.1007/s10570-023-05453-9

Journal information: Advanced Functional Materials

Provided by University of Groningen