This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

trusted source

proofread

Researchers develop high-performance zero thermal expansion composite for precision devices

Recently, a research group led by Prof. Peng Tong from Hefei Institutes of Physical Science (HFIPS), Chinese Academy of Sciences (CAS), significantly improved the negative thermal expansion (NTE) effect of Cu2P2O7, a new but excellent NTE material, and prepared a zero thermal expansion (ZTE) Cu2P2O7/2024Al composite with high specific thermal conductivity and good machinability.

The research results were published in Journal of Materials Science & Technology and Ceramics International.

With the advancement of high-tech fields, it is not possible to adjust the dimensions of precision equipment. However, thermal expansion with temperature is a fundamental property of many regularly used materials that is difficult to control. Combining NTE materials with ordinary positive thermal expansion materials is an efficient way to produce ZTE materials.

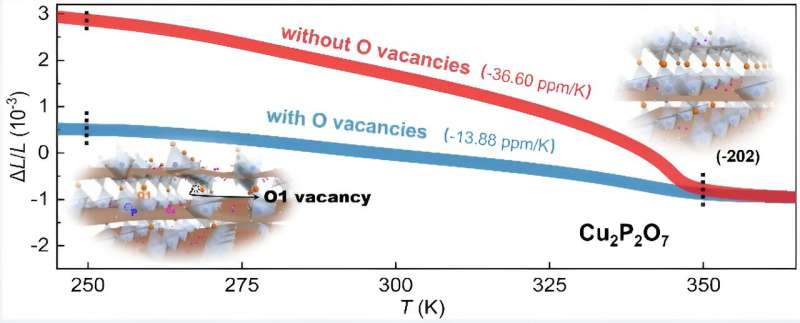

In this study, researchers discovered that increasing the sintering temperature improves the NTE impact of Cu2P2O7 (from -13.88 ppm/K to -36.6 ppm/K at 250-350 K). The vibration of the bridge oxygen atom causes the NTE effect in Cu2P2O7.

The results of temperature dependent X-ray powder diffraction, temperature dependent neutron powder diffraction, and X-ray absorption near edge structure demonstrated that Cu2P2O7 produced at lower temperatures had more oxygen vacancies, resulting in a weaker phase transition and NTE impact.

A series of Cu2P2O7/2024Al composites were made using the powder metallurgy method in a fast-hot-pressing sintering apparatus using enhanced Cu2P2O7 as reinforcement. The composite exhibited ZTE (-0.014 ppm/K at 273-333 K) with up to 50% Cu2P2O7 volume addition.

When compared to other reported isotropic ZTE materials, this ZTE composite had a low density of 3.41g/cm-3 and a high thermal conductivity of 49.7 WK-1m-1, resulting in a high specific thermal conductivity.

Furthermore, its bending strength could reach 205 MPa, and this type of composite had good machinability due to the matching moduli of Cu2P2O7 and 2024Al, as well as a well-bonded interface.

"Our research provided a good candidate NTE material for compositing and a kind of ZTE composite with excellent comprehensive properties which is expected to be used in high-tech fields with high demand of dimension stability," said Xie Lulu, first author of the papers.

More information: L. Lu Xie et al, The enhanced negative thermal expansion in less-oxygen-vacancies copper pyrophosphate, Journal of Materials Science & Technology (2022). DOI: 10.1016/j.jmst.2022.10.054

Lulu Xie et al, Zero thermal expansion, high specific thermal conductivity, and good machinability of Cu2P2O7/2024Al composite, Ceramics International (2023). DOI: 10.1016/j.ceramint.2023.08.240

Provided by Chinese Academy of Sciences