This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

trusted source

proofread

Fabricating fused silica optics with a high laser-induced damage threshold

Residual processing defects significantly reduce fused silica optics' laser-induced damage threshold (LIDT), which seriously limits their performance and lifetime in high-energy laser applications. Extensive research has been conducted to eliminate and suppress these defects, but manufacturing fused silica optics with a high LIDT remains a bottleneck problem.

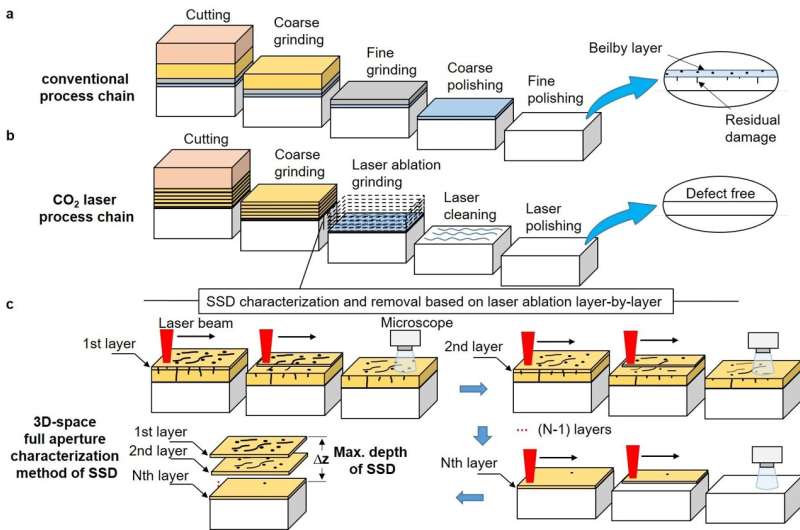

A new laser-based process chain has been developed and reported in a new paper published in Light: Advanced Manufacturing. The scientists, led by Professor Chaoyang Wei and Jianda Shao, can now fabricate fused silica optics with high LIDTs. The process uses a CO2 laser to ablate the optic's surface in a uniform layer-by-layer fashion, which allows for the precise removal of subsurface mechanical damage and surface/subsurface contamination.

The results show that the LIDTs of samples fabricated using the new process chain are significantly higher than those manufactured using conventional methods. This new process represents a promising new direction for fabricating highly damage-resistant fused silica optics for high-energy laser applications.

Residual processing defects significantly reduce the LIDT of fused silica optics, which seriously limits their performance and lifetime in high-energy laser applications. Conventional processing methods have focused on effectively managing subsurface mechanical damage (SSD) during grinding, but this is not always successful.

Additionally, conventional polishing methods can lead to polishing contaminants. Postprocessing techniques such as HF-based etching have been developed to eliminate contaminants and SSD, but these techniques can also introduce new defects.

To further improve the damage resistance of fused silica surfaces, new methods must be developed to address the 3D-space full-aperture characterization of SSD and the introduction of new defects in the postprocessing step.

One promising new method is laser radiation processing of fused silica glass. Since the nature of non-contact and no need for polishing slurry, laser processing has a natural advantage in suppressing defect introduction. A CO2 laser can be used to ablate the optic's surface in a uniform layer-by-layer fashion, which allows for the precise removal of SSD and surface/subsurface contamination.

A CO2 laser process chain has been proposed for manufacturing highly damage-resistant fused silica optics. The process chain includes laser ablation, laser cleaning, and laser melt polishing. First, theoretical and experimental research verified the feasibility of characterizing SSD based on uniform layer-by-layer laser ablation. The SSD characterization method was coupled with the laser ablation grinding process to achieve complete SSD removal. Next, a laser conformal cleaning method was proposed to effectively remove ablation contaminants. Finally, with laser melt polishing, suppression of damaged precursors was realized in the entire process chain, and a fused silica sample with a high LIDT was obtained.

The proposed characterization method provides a new tool for guiding the optimization of finishing processes. This new processing strategy offers a new approach to low-defect manufacturing of fused silica optics.

More information: Xiaocong Peng et al, Laser-based defect characterization and removal process for manufacturing fused silica optic with high ultraviolet laser damage threshold, Light: Advanced Manufacturing (2023). DOI: 10.37188/lam.2023.021

Provided by Chinese Academy of Sciences