This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

proofread

Study explores influence of microwave and hot air drying on the quality of quick-cooking mung beans

Mung bean (Vigna radiata (L.)) is a widely grown legume crop that serves as a sustainable and valuable source of dietary protein, which is rich in essential amino acids, fats, carbohydrates, and a variety of bioactive substances.

However, high temperatures and humidity during storage can cause the seed coat of the bean to harden, leading to hard-to-cook (HTC) defects, which reduce its nutritional value and extend cooking time. With the increasing demand for ready-to-eat foods, there is an urgent need to develop suitable drying methods for quick-cooking beans that retain their nutritional value while addressing the shortcomings of HTC.

Researchers from Nanjing Agricultural University have published an online paper entitled "Effect of microwave and hot air drying on the quality of quick-cooking mung bean" in the journal Food Materials Research on 29 May 2023.

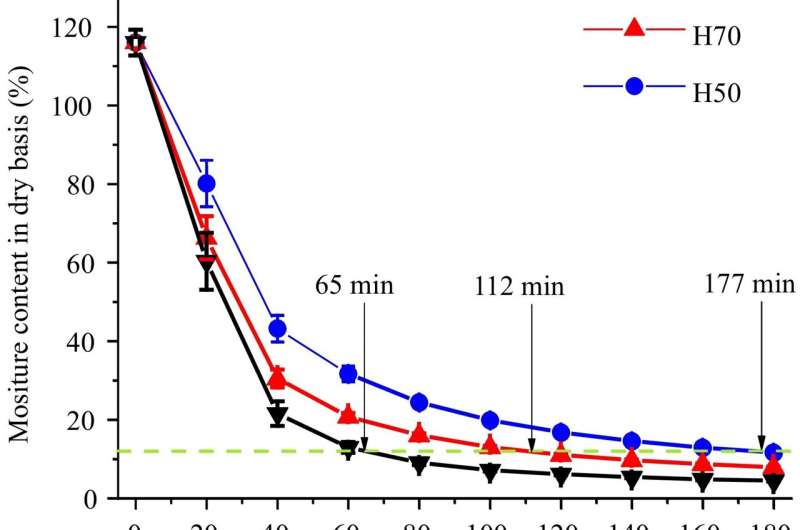

In this study, drying kinetics, energy consumption and quality of dried mung bean (appearance, color, cooking hardness and in vitro digestibility) were compared in hot air and microwave drying. The results showed that all drying curves followed a first-order reaction kinetics model, and the hot air drying method was used to obtain 12% moisture content in mung bean at temperatures of 50°C, 70°C and 90°C for 65, 112, and 177 min, respectively.

Microwave drying with its low power input and higher thermal conductivity as a superior alternative, reduced the drying time substantially to 25–29 min. Moreover, as the microwave power escalated, the drying rate increased and the equilibrium moisture content diminished. Notably, the energy consumption of microwave treatment (0.24–0.29 kW·h) was significantly lower than that of air hot drying and can dramatically shorten drying time.

Visual images demonstrated that the mung beans' shape and volume were better maintained by microwave drying, although darkening of the color may require industrial pretreatment, such as tempering, to improve product quality. Meanwhile, the XRD results showed that microwave drying significantly shortened the drying time, which helped to limit the retrogradation of starch, thus improving the in vitro digestibility of quick-cooking drying mung bean. Finally, the advantages of microwave drying were elucidated in terms of quality formation mechanism of quick-cooking mung bean prepared by microwave and hot air drying.

In conclusion, this study underscores the efficacy of microwave drying as a superior alternative to conventional hot air drying for mung beans. The findings reveal the intrinsic mechanism of quality formation in microwave treatment and provide theoretical guidance for the application of microwave in quick-cooking food preparation.

More information: Yaning Shi et al, Effect of microwave and hot air drying on the quality of quick-cooking mung bean, Food Materials Research (2023). DOI: 10.48130/FMR-2023-0008

Provided by TranSpread