This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Breakthrough injectable hydrogel drug delivery system for advanced medical treatment applications

Researchers from the Department of Mechanical Engineering at the University of Hong Kong (HKU) have recently achieved a remarkable breakthrough in the injectable hydrogel with the development of Fibro-Gel. This groundbreaking innovation successfully overcomes the challenges of scalable manufacturing and on-demand drug release, while also demonstrating exceptional biocompatibility and the potential for vascularization.

The research team was led by Professor Anderson Ho Cheung Shum of the Department of Mechanical Engineering at The University of Hong Kong (HKU) and their collaborators, Professor Michael To's team from The University of Hong Kong-Shenzhen Hospital, and the group of Professor Howard Stone and Dr. Janine Nunes from the Department of Mechanical and Aerospace Engineering at Princeton University.

The latest discovery has been published in Advanced Materials.

Injectable hydrogels are valuable in wound healing due to their injectability, minimal invasiveness, and adaptability to irregular sites. However, challenges include scalable manufacturing, matching properties, and on-demand drug release, limiting control over biophysical cues for endogenous cell direction.

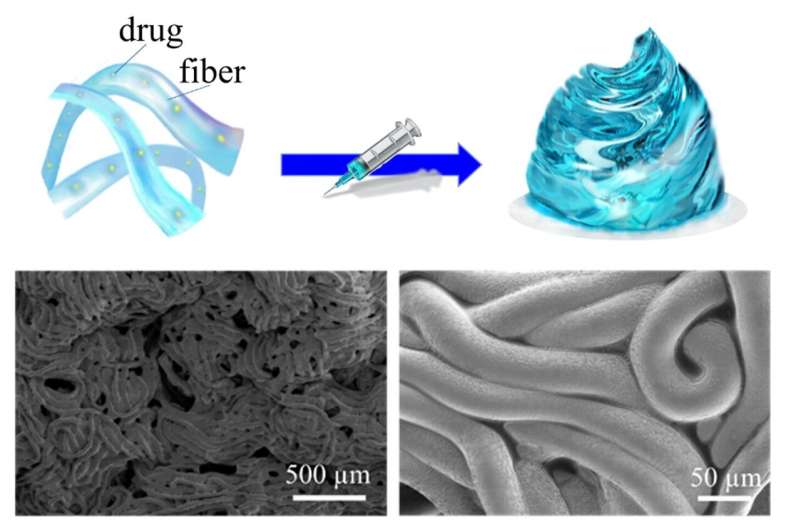

The research team designed and fabricated an oil-free, reaction-free, biomimetic, injectable, and fully scalable Fibro-Gel for wound healing applications. For the first time, Ph.D. student Yanting Shen and postdoctoral fellow DrYuan Liu of the Department of Mechanical Engineering, HKU discovered that Fibro-Gel with controllable physicochemical properties and drug release profiles can be precisely tailored by simply adjusting the microfiber lengths.

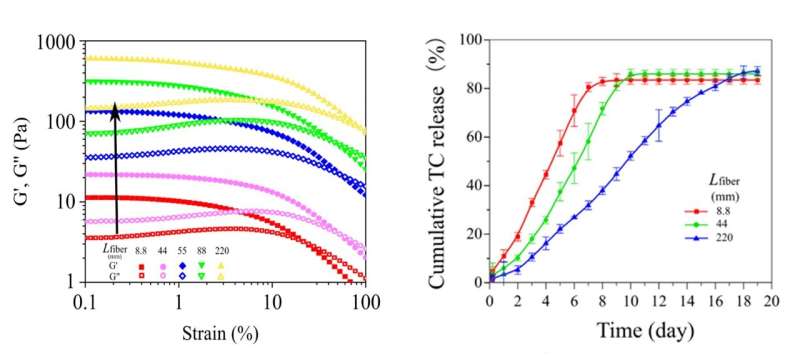

They found that the mechanical properties of Fibro-Gel vary depending on the length of the microfibers. Fibro-Gel with shorter microfibers exhibits lower stiffness and a more fluid-like behavior, resulting in faster rates of drug release. Conversely, Fibro-Gel with longer microfibers demonstrates higher stiffness and a more solid-like behavior, leading to slower drug release rates.

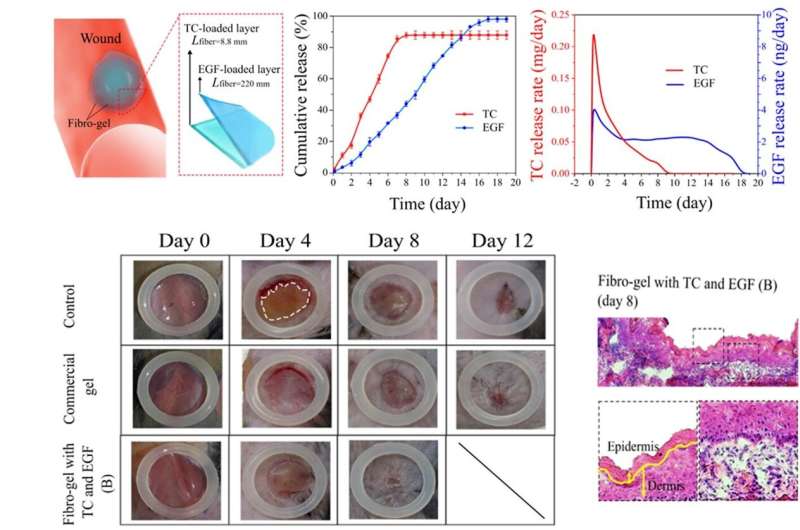

Leveraging this controllable feature, the researchers designed a drug release system with multiple drugs at different drug release rates at the same time, addressing the drawbacks of existing hydrogel systems. Extensive in vitro testing has demonstrated the favorable biocompatibility of Fibro-Gel and its potential to aid vascularization.

This discovery overcomes the limitations of conventional drug delivery via hydrogel. Along with the controllable physicochemical properties suiting different tissues, Fibro-Gel exhibits tremendous potential for the development of advanced therapies and treatment modalities.

To investigate the application of Fibro-Gel in tissue regeneration, the researchers conducted in vivo tests using a mice excision skin model. The results indicate that Fibro-Gel promotes wound healing with an accelerated rate of new tissue regeneration and the appearance of de novo regenerated healthy tissue, in comparison to a commercial gel. Furthermore, the researchers demonstrated that the release of distinct drugs at different rates could further enhance wound healing with higher efficiency using a two-layer Fibro-Gel model.

"Our research on Fibro-Gel has provided valuable insights into the controlled release rates of drugs and the tunable physicochemical properties essential for wound healing," said Ph.D. student Yanting Shen who observed the process, highlighting the remarkable effects of the release of distinct drugs at varying rates from Fibro-Gel on wound healing. "This innovative approach has significantly accelerated the rate of healing, resulting in the formation of intact new tissue."

Professor Shum was optimistic about the collaborative effort, "Our multidisciplinary research collaboration has enabled us to address the topic of wound healing from multiple perspectives, namely, microfluidics, hydrogel and drug delivery, leading to the development of Fibro-Gel. This novel hydrogel has immense potential to address critical medical needs that require more versatile and compatible soft materials."

The successful partnership between HKU and Princeton University, supported by the Research Impact Fund by the Research Grants Council of Hong Kong, exemplifies the power of cross-border collaboration and highlights the significance of pooling expertise to drive groundbreaking research in the field of regenerative medicine.

Professor Shum and his team are dedicated to pushing the boundaries of scientific and engineering discovery and fostering innovation in the biomedical field. He believes this research opens up new possibilities for material systems with extensive biomedical applications, including therapeutic agent delivery for infectious diseases and tissue regeneration.

More information: Yanting Shen et al, Fibro‐Gel: An All‐Aqueous Hydrogel Consisting of Microfibers with Tunable Release Profile and its Application in Wound Healing, Advanced Materials (2023). DOI: 10.1002/adma.202211637

Journal information: Advanced Materials

Provided by The University of Hong Kong