This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

trusted source

proofread

Scientists make common pain killers from pine trees instead of crude oil

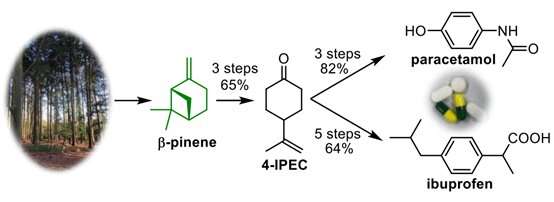

A team of scientists, from the University of Bath's Department of Chemistry and Institute for Sustainability have found a way to create two of the world's most common painkillers, paracetamol and ibuprofen, out of a compound found in pine trees, one which is also a waste product from the paper industry.

It is perhaps not widely known that many common pharmaceuticals are manufactured using chemical precursors derived from crude oil, presenting a niche sustainability challenge as the world targets Net Zero.

The research team from Bath has developed a method of creating a range of pharmaceutical precursors from biorenewable β-pinene, a component of turpentine which is a waste by-product from the paper industry (annual production >350,000 tons).

They successfully converted β-pinene into two everyday painkillers, paracetamol and ibuprofen, which are produced on ~100,000 ton scales annually.

They also successfully synthesized a range of other precursor chemicals from turpentine, including 4-HAP (4-hydroxyacetophenone), which is the precursor of drugs including beta-blockers and the asthma inhaler drug, salbutamol, as well as others widely used for perfumes and in cleaning products.

They hope that this more sustainable "biorefinery" approach could replace the need for crude oil products in the chemical industry.

Dr. Josh Tibbetts, Research Associate in the University's Department of Chemistry, said, "Using oil to make pharmaceuticals is unsustainable—not only is it contributing to rising CO2 emissions, but the price fluctuates dramatically as we are greatly dependent on the geopolitical stability of countries with large oil-reserves, and it is only going to get more expensive."

-

Biorenewable paracetamol produced by the team. Credit: University of Bath -

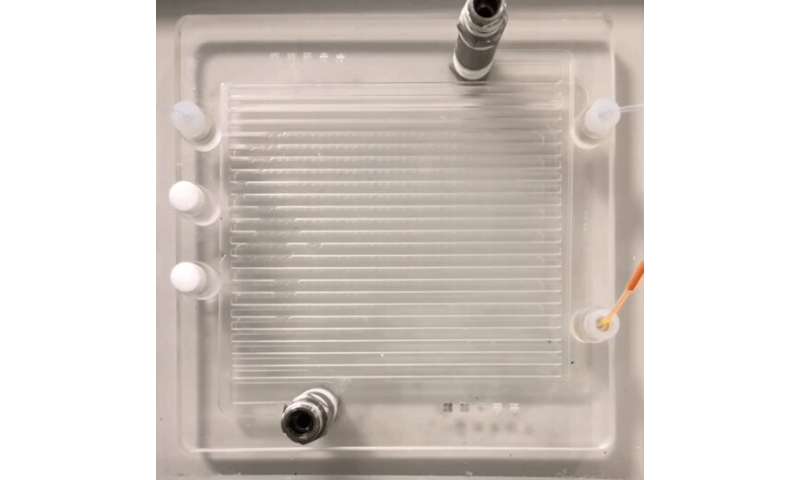

Flow reactor used in the synthesis of paracetamol where starting materials are flowed through in a continuous process to give a constant stream of products. Credit: University of Bath

"Instead of extracting more oil from the ground, we want to replace this in the future with a 'bio-refinery' model."

"Our turpentine-based biorefinery model uses waste chemical by-products from the paper industry to produce a spectrum of valuable, sustainable chemicals that can be used in a wide range of applications from perfumes to paracetamol."

Instead of putting chemicals in a large reactor to create separate batches of product, the method uses continuous flow reactors, meaning production can be uninterrupted and easier to scale up.

While the process in its current form may be more expensive than using oil-based feedstocks, consumers may be prepared to pay a slightly higher price for more sustainable pharmaceuticals that are completely plant-derived.

The findings are published in the journal ChemSusChem.

More information: Joshua Dale Tibbetts et al, Sustainable Syntheses of Paracetamol and Ibuprofen from Biorenewable β‐pinene, ChemSusChem (2023). DOI: 10.1002/cssc.202300670

Provided by University of Bath