This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

proofread

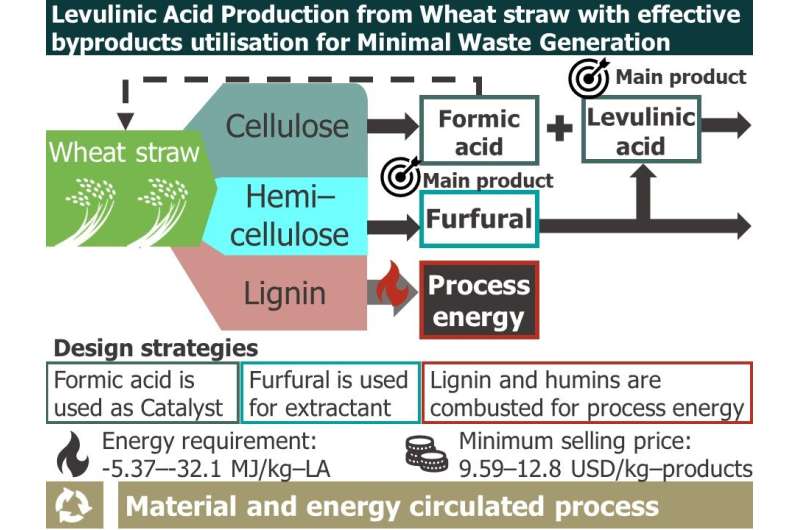

A novel biorefinery process with material and energy circulation by reusing by-products

The research team of Tokyo University of Agriculture and Technology (TUAT) has designed and developed a novel recycling process for producing biomass-derived chemicals by reusing the by-products of the target product. In this study, the research team demonstrated a self-sustaining process that minimizes the usage of external utilities in the chemical process by numerical simulations.

This achievement has significantly contributed to energy conservation by reusing by-products, which had been disposed of in the conventional process in the chemical process to ensure profitability. In addition, while previous processes were designed on a large scale, this study was designed with a biomass supply feasible in all regions.

This is a completely different approach from conventional processes. With this achievement, we can significantly reduce petroleum usage in chemical processes to establish a recycling-oriented society in the future. In addition, for regional revitalization, it is expected to create a chemical industry for local production for local consumption using agricultural and forestry waste in mountainous regions.

The results have been published in Chemical Engineering Research and Design .

Biomass is the renewable carbon resource that can replace fossil resources in chemical production. Among the biomass-derived chemicals, levulinic acid (LA) is attracting attention as a platform chemical because it can be synthesized from cellulose, which makes up about 50% of woody biomass, and is a precursor for a wide range of substances from pharmaceuticals to bio-fuels.

Conventional LA production processes from biomass are large-scale processes with an annual biomass supply of more than 120,000 tons, and had challenges in effectively utilizing all biomass resources.

In response, this research team has developed a process that minimizes the supply of external utilities by reusing by-products produced during the production of LA from biomass as much as possible while still being able to supply all of the required energy from the combustion of by-products.

Specifically, by reusing the by-product formic acid as a catalyst, using a chemical called furfural obtained from biomass as an extraction solvent to purify LA, and combusting the solid by-products, the total process energy was reduced and supplied by itself. Furthermore, it was found that the excess solid by-products could be effectively utilized for building materials and other purposes. We also found that using river water could provide all the cooling needed.

The amount of river water is less than 0.12% of the minimum annual volume flow in the middle reaches of the Naka River in Tochigi Prefecture, located in a rural area of Japan.

Regarding economics, the minimum selling price of LA produced by this process was $9.59 per kilogram, which was higher than the market price of $7.17 per kilogram. The reason is due to the fact that this process allows for thin profit margins to some extent, which is an advantage of large-scale processes, and also because no separation and purification of by-products are performed.

The results of this research indicate that this process can be fully implemented in society for a locally produced and consumed chemical industry using agricultural and forestry waste in mountainous regions.

More information: Ryu Ukawa-Sato et al, Design and techno–economic analysis of levulinic acid production process from biomass by using co-product formic acid as a catalyst with minimal waste generation, Chemical Engineering Research and Design (2023). DOI: 10.1016/j.cherd.2023.02.046

Provided by Tokyo University of Agriculture and Technology