June 28, 2023 report

This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

An isothermal biocatalytic process to manufacture therapeutic oligonucleotides

A team of biochemists at the Manchester Institute of Biotechnology has developed an isothermal biocatalytic process that can be used to manufacture therapeutic oligonucleotides in large volumes. In their paper published in the journal Science, the group describes their process and possible medical applications.

Oligonucleotides (short base pairs of RNA or DNA molecules) have been used to treat several rare diseases. But the process of manufacturing them in large quantities is difficult for more general use. More recently, the development of therapies such as siRNA inclisiran to reduce cholesterol in the bloodstream has put pressure on biochemists to develop a less difficult process.

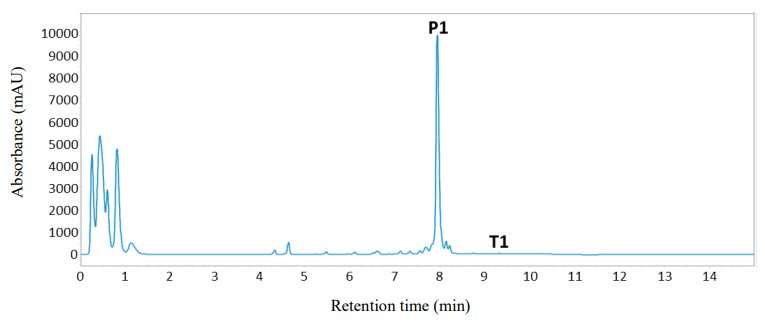

In this new effort, the team developed a one-pot manufacturing process. They note that it can be conducted in an aqueous solution and uses polymerase enzymes to extend template strands and an endonuclease enzyme to release the final product, allowing for the templates used in the process to be used repeatedly.

The process starts by adding nucleoside triphosphates to an aqueous solution, which drives a template-dependent synthetic reaction. Adding an extended template results in product cleavage, leading to the creation of endonuclease V, part of which can be removed for use as it is. The other part is then exposed to yet another template made using inosines, and the material that makes it through the final template consists of the desired oligonucleotides.

The research team suggests that in addition to making the manufacture of therapeutic oligonucleotides less expensive, it also makes it more scalable. To prove their claims, they used their new method to manufacture several well-known therapeutic oligonucleotides, such as pegaptanib, which has been used to treat macular degeneration.

They were able to produce approximately 2g per liter, but suggest the process should allow for amounts over 10g per liter—and at some point, as much as 100g per liter. They plan to continue fine tuning the process to manufacture more kinds of oligonucleotides. The team has partnered with Novartis, which already produces inclisiran, to further develop the scaling process.

More information: E. R. Moody et al, An enzyme cascade enables production of therapeutic oligonucleotides in a single operation, Science (2023). DOI: 10.1126/science.add5892

Journal information: Science

© 2023 Science X Network