This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Framework structure with nanoscopic insulation enables components for soft robotics and flexible electronics

Classical robots, such as those used for manufacturing, can lift heavy loads and repeat automated processes precisely. But they are too rigid and bulky for delicate work and interaction with humans. The research field of soft robotics works on the development of robots made of soft, organic materials and flexible technical components. Materials researchers at Kiel University have now developed a novel soft conductive material.

Unlike conventional soft conductors, it shows remarkably stable electrical properties even upon deformation. The reason for this is the special structure of the material and a nanoscopic insulating thin film coating. The research team published its results in the current issue of the journal Advanced Functional Materials.

Constant electrical resistance even during deformation

Unlike classical robots, humans and animals can perform fluid and fine movements and adapt them to their environment. Inspired by nature, soft robotics therefore relies on elastic, organic materials made of carbon instead of conventional, rigid metals. In addition, soft robots need elastic electrical conductors for communication between their sensors and actuators.

"Conventional conductors made of metal conduct electricity well, of course, but they are too rigid for flexible components. Upon deformation they change their electrical resistance and this affects their use in soft robotics," says Dr. Fabian Schütt, the head of the junior research group Multiscale Materials Engineering at the Chair of Functional Nanomaterials at Kiel University.

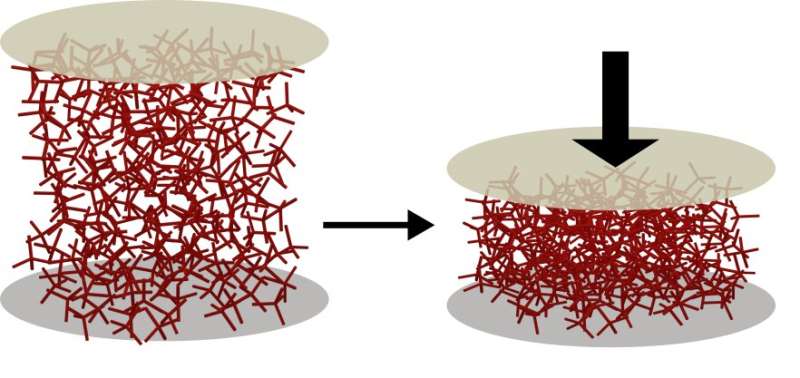

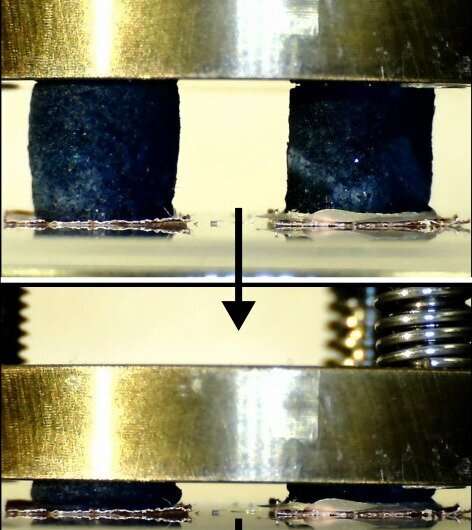

In contrast, the resistance of the material, which Schütt developed together with colleagues at the Institute of Materials Science at Kiel University, remains constant when it is deformed. "Both, the initial electrical and mechanical properties are retained during long-term cycling, even after 2000 cycles at 50% compression," says Igor Barg, a doctoral researcher at the Chair for Multicomponent Materials and the first author of the article.

By combining different expertise within the Priority Research Area KiNSIS (Kiel Nano, Surface and Interface Science) of Kiel University they created a material made of fine wires that looks like a dark sponge. The wires consist of interconnected microtubes made of an electrically conductive polymer. This delicate network structure makes the material ultra-light and at the same time extremely elastic.

Nanoscopic insulation film protects the electrical properties of the material

"Stretchable, sponge-like conductors have already been researched for several years. But as soon as they are deformed, their resistance also changes due to the so-called piezoresistive effect," Barg explains. To avoid this effect, the team coated their material with a non-conductive, nanoscopic thin film of Polytetrafluorethylene (PTFE).

"You can think of it as a classic power cable," says Barg. The layer prevents the wires from coming into direct contact with each other during compression and creating new electrically conductive paths. Thus, the resistance remains constant even upon large deformations. The insulation also improves the mechanical stability of the wires and protects their electrical properties from external influences such as moisture.

In order to coat this highly porous framework structure, a special technique is needed. Dr. Stefan Schröder is head of the junior research group Functional CVD Polymers at the Chair for Multicomponent Materials and works with the initiated chemical vapor deposition (iCVD).

By this it is possible to even coat materials with complex structures and surfaces conformally: Bringing together different gases in a reactor sets off a chemical reaction and a thin polymer film begins to grow on the material to be coated. "Since this coating is only a few nanometers thin, the wires remain elastic and the total weight of the material hardly increases," Schröder explains.

Applications in medical technology are also conceivable

"This example shows very well how we can use nanoscale coating to specifically change the properties of our framework structures, which are up to several cubic centimeters in size, and even create completely new functions," says Schütt.

"By combining our methods, other applications, including commercial ones, might be possible in the future, for example in medical technology or energy storage," adds Schröder. They now want to investigate these possibilities in further joint research projects.

More information: Igor Barg et al, Strain‐Invariant, Highly Water Stable All‐Organic Soft Conductors Based on Ultralight Multi‐Layered Foam‐Like Framework Structures, Advanced Functional Materials (2023). DOI: 10.1002/adfm.202212688

Journal information: Advanced Functional Materials

Provided by Kiel University