Stepwise magnetic self-assembly of micropillar arrays with long range order

Magnetically responsive microtextured surfaces have the advantage of being controlled remotely (i.e., no contact is required) at ambient conditions and short response times. Previously, synchronized bending or twisting actuations of micropillar arrays were demonstrated by programming the arrangement of the magnetic particles and by employing anisotropic micropillar geometry. In this case, magnetic particles are included in a polymer matrix at low concentrations to avoid magnetic interference and thereby achieve synchronized actuation. Researchers from Inha University (Jeong Eun Park and Jeong Jae (JJ) Wie), Air Force Research Laboratory (Augustine Urbas and Zahyun Ku), and Lawrence Livermore National Laboratory (Sei Jin Park) recently reported an opposite strategy to induce magnetic self-assembly of micropillar arrays. Highly concentrated magnetic micropillars act as micromagnets and collectively assemble with neighboring pillars under an applied magnetic field. For facile actuation, flexible rubber is utilized for pillar-base while relatively rigid and magnetically responsive pillar-tops undergo the magnetic assembly. As the pillar-base is magnetically inert and fixed to substrate, self-assembly of periodically arranged micropillars can repeat reversible and reproducible assembly and recovery by modulating the external magnetic field.

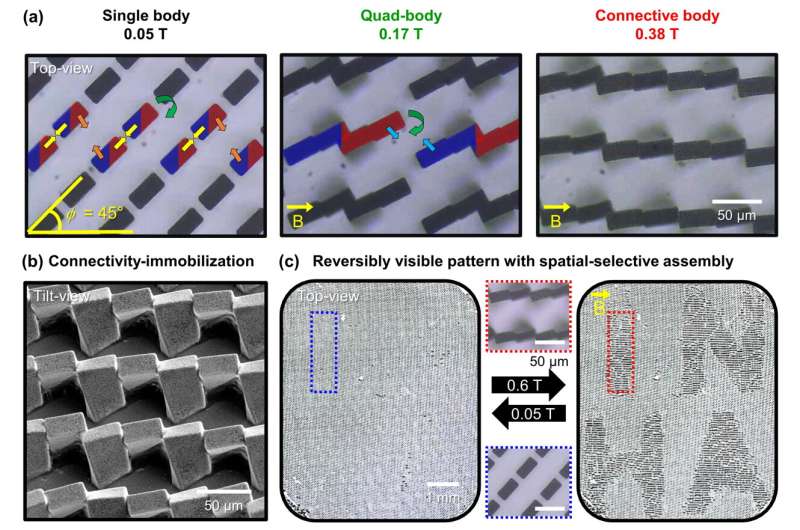

When a magnetic field is applied parallel to the long axis of rectangular micropillar arrays, magnetic dipoles (namely N and S poles) are created in the micropillars. As the magnetic flux density increases, two adjacent dipolar micropillars are assembled in pairs through quadrupolar attraction. Meanwhile, the pairs are assembled with one of the other pairs (i.e., quad-body) where the long axis of rectangular micropillars is placed to offset 45 degrees with respect to the magnetic field axis. Magnetic twisting deformation of the micropillars is also generated since micromagnet-like micropillars want to be parallel to pillars' long axis and applied magnetic field. Subsequently, under continuously increased magnetic flux density, quad-bodies are assembled with other quad-bodies while undergoing further twisting motion. As a result, a highly connective long-range order is achieved at the pillar tops with a twisting degree of ~40 degrees. Furthermore, the researchers demonstrated that the magnetically assembled micropillars can be frozen in place even after the magnetic field is removed by treating with a water-soluble binder.

Additionally, the effect of magnetic pillar geometries on the minimum magnetic flux density required to initiate the assembly was investigated by comparing the assemblies of square and circular micropillars which have identical interpillar spacing and widths fixed at 30 µm. Lower magnetic flux density threshold was recorded for structures circular cross sections than those with square cross sections due to their lower area moment of inertia. The threshold magnetic flux densities were lower for higher aspect ratio structures as well. The lower thresholds were observed for both assemblies of two single structures into a pair as well as the assembly of paired structures to achieve long-range connectivity.

Following are functional demonstrations to emphasize the broad impact and macroscopic expandability in shape-reconfigurable microtextured surfaces with stepwise magnetic self-assembly. First, the researchers present magnetically switched visible/invisible letter patterns by locating two contrasting areas in the letter and background part. While the micropillars in the letter part are connectively assembled, the micropillars in the background region are not assembled even as magnetic flux density increases up to 0.6 T. The letter is clearly observed right after the magnetic field is applied due to differences in contrast, which disappears immediately when the magnetic field is removed as the pillars revert back to the original state. Second, the researchers also demonstrated the macroscopic liquid spreading in bi-direction (x- and y-axes) that are decoupled from each other. The liquid droplet is initially pinned on hydrophobic micropillar arrays, but under a magnetic field, the pairwise (//x) and connective (//y) assembly reduce the interpillar spacings, allowing the droplet to depin and spread.

This unprecedented mechanism of stepwise microscopic self-assembly will provide insights into magnetic shape-reconfiguration of actuators and soft robotic systems, and the macroscopic demonstration of the surface change can potentially benefit a broad range of applications in the future.

More information: Jeong Eun Park et al, Programmable Stepwise Collective Magnetic Self-Assembly of Micropillar Arrays, ACS Nano (2022). DOI: 10.1021/acsnano.1c10844

Journal information: ACS Nano

Provided by Inha University