Researchers develop high-entropy-alloys–based, high-temperature solar absorption coatings

As a newcomer in the alloy material world, high-entropy alloys exceed the traditional alloy design concept as they possess more than five elements, and generally exhibit a simple solid solution structure due to their high configuration entropy. With excellent mechanical properties, ability to withstand heat, as well as their resistance to wear, corrosion and irradiation, high-entropy alloys have great potential for development in the renewable energy industry.

Recently, a research team led by Associate Professor GAO Xianghu and Professor LIU Gang at the Lanzhou Institute of Chemical Physics of the Chinese Academy of Sciences (CAS) prepared a series of high-entropy-alloy-based, high-temperature, solar-selective absorbing coatings through component modulation, conformational entropy optimization and structural design using high entropy nitrides.

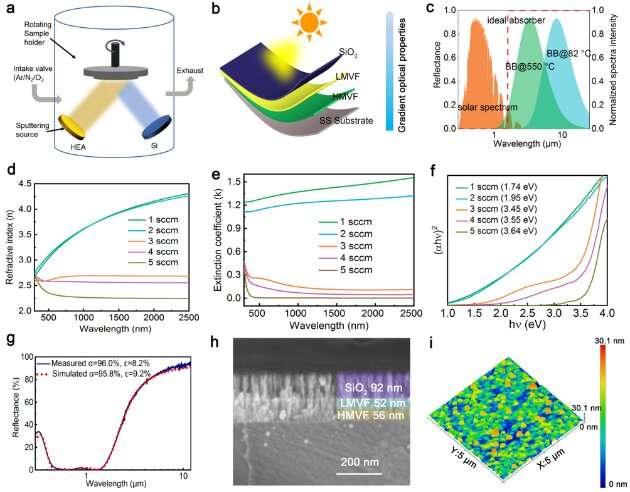

The researchers designed a color solar-selective absorbing coating consisting of an infrared reflective layer of aluminum, high-entropy alloy nitride, high-entropy alloy nitrogen oxide and silicon dioxide, which enables a high solar absorption of 93.5 percent and a thermal emittance of less than 10 percent.

Subsequently, they found that a single layer of high-entropy alloy nitride ceramics also had good intrinsic absorption properties, and therefore prepared a coating with a simple structure. They used high-entropy alloy nitride as the absorption layer and SiO2 or Si3N4 as the antireflective layer, and obtained a coating with an absorption of 92.8 percent and an emissivity of less than 7 percent, which showed favorable thermal stability in a vacuum at 650 degrees Celsius for 300 hours.

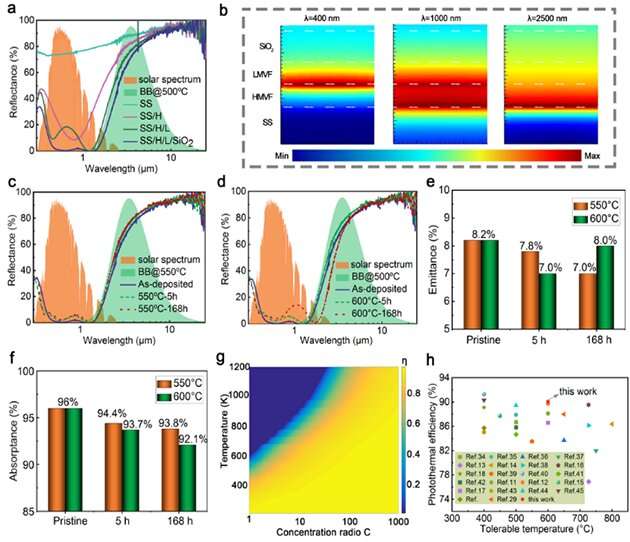

To further enhance the absorption capacity of the absorber, the researchers chose stainless steel as the substrate, low-nitrogen content high-entropy alloy films as the main absorption layer, high-nitrogen content high-entropy alloy films as the extinction interference layer, and SiO2, Si3N4 or Al2O3 as the antireflection layer, forming a structure with gradually decreasing optical constants from the substrate to the surface. A combination of optical simulation and magnetron sputtering methods were used to improve the preparation efficiency, which contributed to an excellent solar absorption of 96 percent and a low thermal emission of less than 10 percent.

They then investigated the light absorption mechanism using finite-difference time-domain simulation. After annealing for 168 hours at 600 degrees Celsius in a vacuum, the high-entropy-alloy, nitride-based absorber still maintained good optical properties, indicating outstanding thermal stability. The photothermal conversion efficiency of the absorber was calculated at different operating temperatures and concentration ratios, and the efficiency was able to reach 90.1 percent when the operating temperature was 550 degrees Celsius and 100 suns.

Compared with the state-of-the-art absorber reported recently, the high-entropy-alloy-based absorber exhibited both excellent photothermal conversion efficiency and thermal stability.

The absorbers were deposited on different substrate materials, which maintained excellent optical properties, and achieved large-scale preparation on aluminum foil. Through the study of absorption spectra at different incident angles, it was found that the absorption coating had good absorption in the range of the incident light angle of 0–60°. Under radiation from simulated sunlight, the temperature of the coating surface exceeded 100 degrees Celsius, indicating that the material has great potential to be applied in the field of interfacial water evaporation.

More information: Hui-Xia Guo et al, A novel multilayer high temperature colored solar absorber coating based on high-entropy alloy MoNbHfZrTi: Optimized preparation and chromaticity investigation, Solar Energy Materials and Solar Cells (2020). DOI: 10.1016/j.solmat.2020.110444

Cheng-Yu He et al, Further investigation of a novel high entropy alloy MoNbHfZrTi based solar absorber coating with double antireflective layers, Solar Energy Materials and Solar Cells (2020). DOI: 10.1016/j.solmat.2020.110709

Cheng-Yu He et al, Scalable and highly efficient high temperature solar absorber coatings based on high entropy alloy nitride AlCrTaTiZrN with different antireflection layers, Journal of Materials Chemistry A (2021). DOI: 10.1039/D0TA09988K

Cheng-Yu He et al, Highly Enhanced Thermal Robustness and Photothermal Conversion Efficiency of Solar-Selective Absorbers Enabled by High-Entropy Alloy Nitride MoTaTiCrN Nanofilms, ACS Applied Materials & Interfaces (2021). DOI: 10.1021/acsami.0c23011

Cheng-Yu He et al, Toward a Scalable and Cost-Conscious Structure in Spectrally Selective Absorbers: Using High-Entropy Nitride TiVCrAlZrN, ACS Applied Energy Materials (2021). DOI: 10.1021/acsaem.1c00918

Cheng-Yu He et al, Scalable and Ultrathin High‐Temperature Solar Selective Absorbing Coatings Based on the High‐Entropy Nanoceramic AlCrWTaNbTiN with High Photothermal Conversion Efficiency, Solar RRL (2021). DOI: 10.1002/solr.202000790

Cheng-Yu He et al, Greatly enhanced solar absorption via high entropy ceramic AlCrTaTiZrN based solar selective absorber coatings, Journal of Materiomics (2020). DOI: 10.1016/j.jmat.2020.11.010

Journal information: Solar Energy Materials and Solar Cells , Journal of Materials Chemistry A , ACS Applied Materials and Interfaces

Provided by Chinese Academy of Sciences