Phosphorescent material inspired by 'glow in the dark' wood

Scientists have harnessed the natural ability of wood to faintly glow to develop a new sustainable phosphorescent material that could potentially be used in a wide number of applications, from medical imaging and optical sensing to 'glow in the dark' dyes and paints.

An international team of researchers led by North East Forestry University (China) and the University of Bath (UK) investigated the natural phosphorescent properties of lignin, a major component of wood.

Room-temperature phosphorescence (RTP) is when a material absorbs energy with a short wavelength (such as UV light) and then emits it as visible light. This contrasts with fluorescent materials, which immediately emit the light again and stop glowing when the light is switched off.

The researchers found that basswood naturally and weakly phosphoresces, releasing light for a few milliseconds due to lignin being trapped within a 3-D matrix of cellulose.

This inspired them to mimic the glowing properties by crosslinking lignin within a 3-D polymer network, which caused it to glow visibly for around one second.

They found by tweaking the cavity sizes within the network, and varying drying times of the polymer, they could alter the duration of the phosphoresce.

Professor Tony James, from the University of Bath's Centre for Sustainable Circular Technologies (UK), said that "all lignin glows weakly, but most of the light energy is lost by vibration or movement of the lignin molecules, meaning it isn't clearly visible to the naked eye."

"We've found that immobilizing the lignin in an acrylic polymer means more energy is emitted as light—in other words, the less it rattles about, the more it glows!"

"Most current phosphorescent materials are either toxic or difficult to prepare, so we wanted to develop a new material that overcame these limitations."

"Although there is room for improvement, our new material shows great potential for making a more stable, sustainable, biodegradable non-toxic phosphorescent material that could be used in a range of applications."

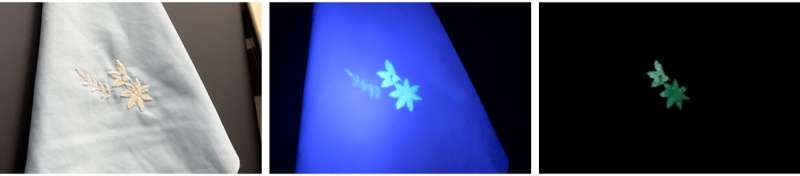

To demonstrate the new material, the team used them to dye threads that could be used in luminescent textiles. This has potential use for the easy identification and the anti-counterfeiting protection of luxury textiles or bags.

Lead corresponding author on the paper Professor Zhijun Chen, from the Engineering Research Center of Advanced Wooden Materials at Northeast Forestry University (China), said: "It is indeed an unexpected and interesting discovery.

"We think this work will not only provide a new option for sustainable afterglow materials but is also a new route for the value-added utilization of lignin, which is the main naturally occurring aromatic polymer, and the pulping industry produces 600 trillion tons per year."

The team's research is published in Cell Reports: Physical Science.

More information: Jingwen Yuan et al, Sustainable afterglow materials from lignin inspired by wood phosphorescence, Cell Reports Physical Science (2021). DOI: 10.1016/j.xcrp.2021.100542

Journal information: Cell Reports Physical Science

Provided by University of Bath