Newly proposed strategy offers smart flexible neural electrode with high efficiency

With rapid development of smart flexible electronics in wearable and implantable fields, it is urgent to prepare biomimetic electrode materials with simple operation, good biocompatibility and low cost, to obtain better stimulation/recording performance.

Traditional flexible electronic devices have disadvantages of low adhesion, easy delamination and failure in the fabrication process.

Although the polymerization process will be prolonged, the dopamine (DA) and its derivatives are promising for the fabrication of functional films and devices with excellent conductivity, bioadhesion and long-term stability.

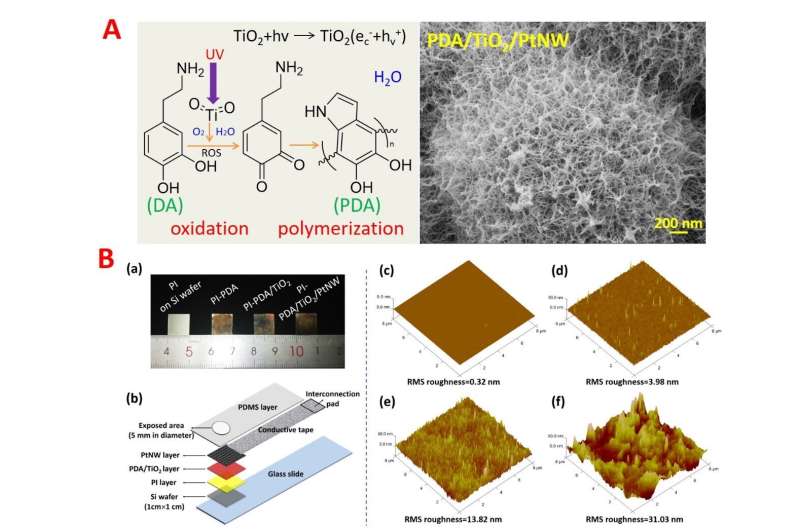

Based on their previous work on neural interfaces (Electrochia Acta, Advanced Materials Interfaces), Prof. Wu Tianzhun's group from the Shenzhen Institutes of Advanced Technology (SIAT) of the Chinese Academy of Sciences proposed an accelerated deposition process using ultraviolet (UV) irradiation with the existence of nanotitanium dioxide (nano-TiO2) to realize a rapid and stable synthesis of polydopamine (PDA) films.

The researchers also proposed in situ deposition process of nanostructured coatings such as platinum nanowire (PtNW) on PDA adhesive layer for better electrical performance.

This method reduced the time of PDA polymerization process to less than 1 h. It also increased the platinum (Pt) chelating rate with PDA (<1h) at room temperature, which was more than 10 times faster than the traditional photo-oxidation method.

Compared with electrodes of the same size based on Ti/Pt sputtering, the impedance of the proposed PDA/TiO2/PtNW coated electrode was reduced by 99.74%.

An extremely high cathodic charge storage capacity (CSCc) was also observed, which was about 106.5 and 1.6 times higher than that of Ti/Pt and PDA/PtNW electrodes, respectively.

In addition, PDA/TiO2/PtNW electrodes presented significant photocurrent polarization responses with a stable current of -136.1 μA, showing excellent charge transfer and UV absorption capacities.

This co-deposition method has demonstrated potential to speed up the polymerization process and enhance the electrical performance for flexible electrodes with low cost.

This work provides a new idea for the preparation of flexible electrodes and can be widely used in practical applications such as neural implants, biosensors, drug carriers and photoelectric electrode materials.

The study, titled "Fast Polymerization of Polydopamine Based on Titanium Dioxide for High-Performance Flexible Electrodes," was published in ACS Applied Materials & Interfaces.

More information: Zhaoling Huang et al. Fast Polymerization of Polydopamine Based on Titanium Dioxide for High-Performance Flexible Electrodes, ACS Applied Materials & Interfaces (2020). DOI: 10.1021/acsami.9b19875

Journal information: ACS Applied Materials and Interfaces

Provided by Chinese Academy of Sciences