July 9, 2019 report

A closer look a magnesium shows very small samples are much more ductile than thought

A team of researchers affiliated with several institutions in China and the U.S. has found that very small samples of magnesium are much more ductile than thought. In their paper published in the journal Science, the group describes their study of the metal using an electron microscope and what they found. Gwénaëlle Proust, with the University of Sydney, has published a Perspective piece on the work done by the team in the same journal issue.

As engineers around the world look for ways to make more efficient cars, planes and other vehicles, they are studying new, lighter materials. One such material, magnesium, is interesting because it is just as strong as aluminum, but 35 percent lighter. Up until now, the metal has rarely been used because it is too difficult to process into parts. It is also much less resistant to corrosion. Still, interest in the metal persists—many in the field believe it is only a matter of finding the right elements to mix with it. In this new effort, the researchers report that they have found very small samples of magnesium are more ductile than previously thought.

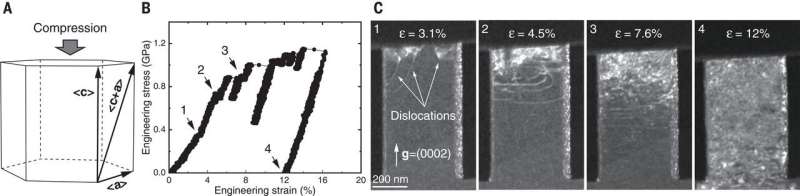

The reason that magnesium is less amenable to conformity than other bendable metals is because of the way its atoms arrange themselves. Atoms such as aluminum are arranged in a cubic structure, which makes it relatively easy to make desired deformities. Magnesium atoms, in sharp contrast, are arranged in a hexagonal pattern. Prior research has shown that when a metal such as aluminum is deformed at room temperature, atoms are displaced along a line in the crystal allowing for dislocations in multiple ways. With magnesium, the possibilities are more limited. To better understand those limitations, the researchers used electron microscopy mechanical testing techniques on a micron-sized sample of magnesium. The technique allowed them to see exactly what happened while applying sheer forces at the atomic level and at room temperature.

The researchers report that the crystal showed surprising ductility—they were able to force dislocations along two planes, something not seen in larger samples. They plan to keep working with the metal to see if they can find a way to force similar dislocations in larger samples—possibly paving their way for use in real-world applications.

More information: Bo-Yu Liu et al. Large plasticity in magnesium mediated by pyramidal dislocations, Science (2019). DOI: 10.1126/science.aaw2843

Journal information: Science

© 2019 Science X Network