Timken turns to neutrons to get its bearings on internal stresses

Bearings are used in many common applications such as wheels, drills, and even toys like the popular fidget spinner. Those applications and others like them rely on bearings to allow for smooth, efficient motion for millions of rotations.

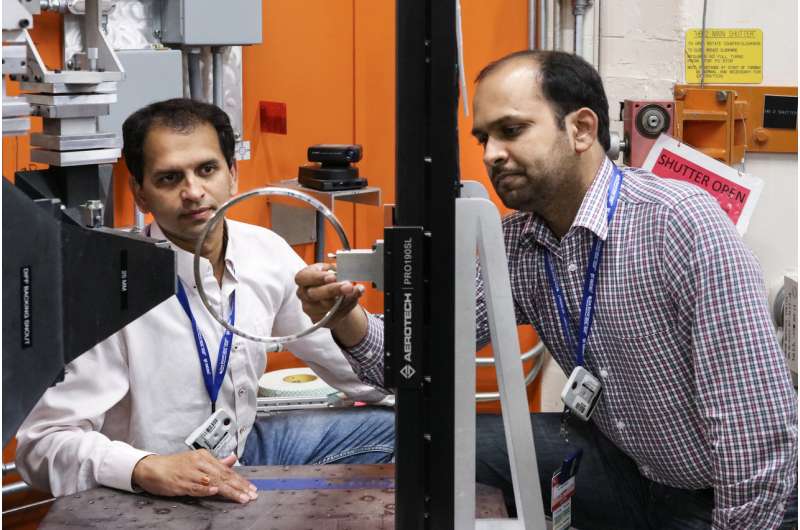

Researchers from The Timken Company, a leading international manufacturer of bearings, are using neutron scattering at the Department of Energy's (DOE's) Oak Ridge National Laboratory (ORNL) to extend the lifetime of bearings by gaining a better understanding of how internal residual stresses created during the manufacturing process affect their performance.

Bearings are manufactured with precision to have tight tolerances and fit perfectly and are designed to last for many years under extreme loads and extensive use and operation. Performance is especially important in fields like aerospace and mining where safety is vital. However, residual stresses—which are small internal elastic deformations in the material's structure—can have a significant impact in reducing a bearing's lifetime and reliability.

"Residual stresses are generated mainly by the manufacturing process," said Vikram Bedekar, a materials specialist at Timken. "All of the processes they go through—reshaping and the exposure to high heat—create residual stress. If you have a lot of stresses, the part can distort. It could distort so much that you can't use or recover the part."

In general, manufacturing bearings begins with steel formed to the shape of a ring. Next, a lathe is used to get the desired size. At that point, the part is still "green," says Bedekar, which means it is still considered soft and not ready for use. A heat treatment is then applied to harden the material. Finally, the part is finished using a lathe or grinder to remove excess material.

Neutrons provide researchers with unique insights into a material's atomic structure because of their highly penetrating properties. Previously, the researchers were using laboratory x-rays to look at bearings, but the researchers could only probe up to 200 microns inside of a bearing. Neutrons give them the capability to look at entire sections of bearings at greater depths.

"Standard x-rays aren't strong enough to go all the way through a section," said Bedekar. "Neutrons are the only way to pass through it and see inside."

Using the Neutron Residual Stress Mapping Facility (NRSF2), HB-2B, at ORNL's High Flux Isotope Reactor (HFIR), the researchers were able to map out the differing internal stresses from each step in the manufacturing process. The neutron data allowed them to observe how a bearing's stress state changes with each iteration. The researchers say they chose to use NRSF2 because it is uniquely suited for this type of experiment.

"We were looking for what we can do in terms of residual stress mapping," said Rohit Voothaluru, a product development specialist at Timken. "We came to NRSF2 because we felt that we could get the whole gamut of samples characterized and see the residual stresses."

The team says they intend to use the residual stress mapping data to improve their computational models for improved internal stress predictions and optimized manufacturing processes.

"Eventually, we can tailor the processing or tailor the residual stress to the desired performance of the bearing," said Bedekar.

"We have a computational model today that can qualitatively provide direction," said Voothaluru. "But to have a more fundamentally driven quantitative model that's based on the actual physics of the process, while also capturing the real-time subsurface residual strain, is something that requires extensive empirical validation. We want to validate our model and take it to the next level."

Provided by Oak Ridge National Laboratory