December 11, 2018 feature

Field-responsive mechanical metamaterials (FRMMs)

In a recent study published in Science Advances, materials scientists Julie A. Jackson and colleagues presented a new class of materials architecture called field-responsive mechanical metamaterials (FRMM). The FRMMs exhibit dynamic control and on-the-fly tunability for designing and selecting the construct's composition and structure. Typically, properties of mechanical metamaterials are programmed and set when the architecture is designed and constructed, without changing in response to shifting external environmental conditions or applications thereafter. The diverse characteristics of FRMMs were first demonstrated by printing complex structures of polymeric tubes filled in with magnetorheological (MR) fluid suspensions to allow remote magnetic fields to control the materials. Accordingly, the scientists observed rapid, reversible and sizable changes of the effective stiffness in the new metamaterial constructs.

Synthetic materials often mimic cellular structures such as teeth, bone and bird beaks in nature to replicate their excellent strength and toughness relative to density. Advanced materials are bioengineered to mimic stochastic (random) cellular structures in the form of polymers and metal foams for structural and functional applications. Nature can also create periodic architectures by evolutionary design, where ordered cellular structures outperform the stochastic counterparts as seen with defensive armor shells and dactyl clubs in crustacea. In the lab, additive manufacturing techniques and 3-D printing are used to engineer cellular structures with nano-, micro-, meso- and macro-scale features that exhibit unique combinations of mechanical, functional and thermal properties. Often referred to as metamaterials, the structures have demonstrated innovative characteristics, including:

- Lightweight, yet stiff and strong architecture in 3-D ceramic nanolattices

- High mechanical resilience in graphene periodic 3-D aerogel microlattices.

- Negative Poisson's ratio in origami-based metamaterials.

- Elasto-mechanical "unfeelability" cloaks and invisibility cloaks

- Multimaterial layouts with negative coefficients of thermal expansion.

These materials combine two or more contrasting features for unique properties, but their architecture remains fixed in time after fabrication. As a result, the materials cannot respond and adapt to changing external conditions. Adaptable and responsive materials are increasingly engineered via 4-D printing, in which the fourth dimension represents time, presently emerging as a new research area in materials science.

The term 4-D represents 3-D printed materials that can change shape or function in response to external conditions or stimuli, including mechanical force, swelling and magnetic fields. The existing demonstrations, however, lack deterministic control of mechanical properties or exhibit slow kinetics for the intended chemical transformations. In the present study, Jackson et al., reveal a new class of field-responsive mechanical metamaterials (FRMM) that are 3-D printed to exhibit programmable, predictive, reversible and controlled mechanical properties in rapid response to a remote magnetic field.

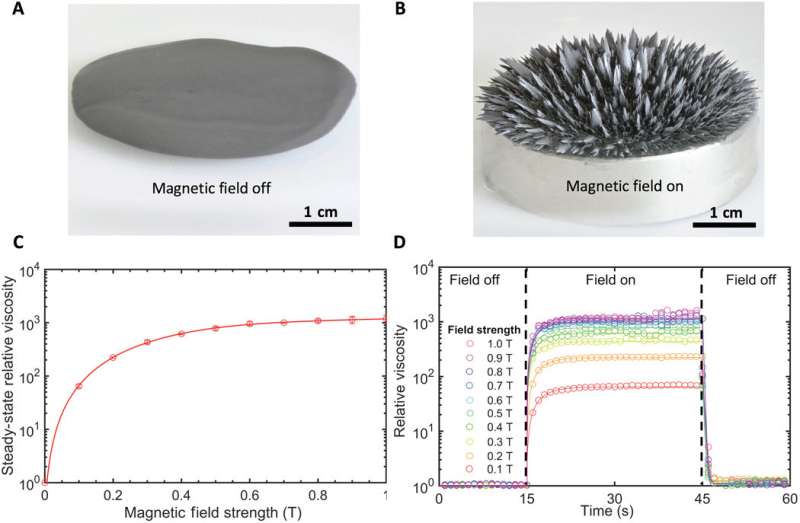

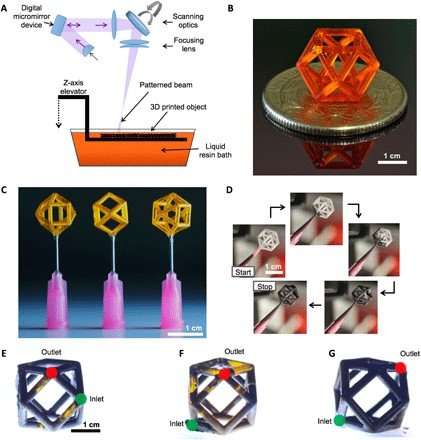

The 3-D-printed hollow polymer tubes or struts that form the building blocks of lattices were filled with magnetorheological (MR) fluid suspensions. The scientists used the LAPµSL system for custom layer-by-layer 3-D printing by projecting UV light patterns onto a photocurable resin to construct 3-D structures from a stack of 2-D images. For consistency, they replicated a previously established protocol on microstereolithography. The MR fluids contained ferromagnetic microparticles in nonmagnetic liquids that could rapidly change viscosity in response to an applied magnetic field. In the absence of a magnetic field, the MR fluid was liquid-like in behavior, with randomly distributed particles that flowed freely to form a pool on a planar substrate. When a magnetic field was applied, the particles aligned into chains along the field lines and formed a spicular array of blade-like structures that resembled stalactite deposits. The fluid viscosity monotonically increased to reach a saturation plateau at a magnetic field strength of ~ 0.3 T.

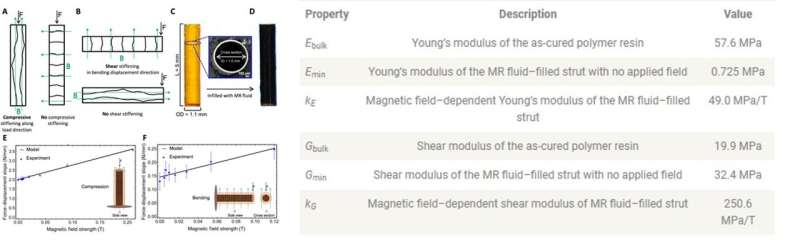

In the study, magneto-mechanical tests were conducted with compression and cantilever bending. Each cylinder (strut) was filled with commercially available MR fluid, which comprised of 50 percent carbonyl iron particles (ranging from 4 to 20 µm) in a hydrocarbon particle stabilizer oil. Each magneto-mechanical test was repeated at several magnetic field strengths, where the field was aligned in parallel to the direction of applied force to obtain a series of force-displacement curves. Among the diverse orientations, the effective stiffness was largest when the field applied was parallel to the direction of the force. The tests were used to calibrate the model at the level of a single strut and ultimately predict the field response of a bigger lattice architecture.

The scientists used a standard composite beam theory, where the analysis assumed the Euler-Bernoulli bending theory to derive a model of the strut. The theory included the effective elastic stiffness of the MR-fluid and elastic stiffness of the struts (Young's modulus). The analytical model assumed a linear relationship between the mechanical strength and increase in the magnetic field. The experiments were kept below the threshold value of 0.3 T since the MR fluid was previously observed to saturate at this value.

The scientists showed the feasibility of the fabrication and mechanical testing approach for more complex architectures by 3-D printing cuboctahedron unit cells using the LAPµSL process. The unit cells were removed of any prepolymer liquid resin and injected with the MR fluid. The filling in (or infilling) procedure was successful when the structure was oriented to prevent entrapped gas bubbles.

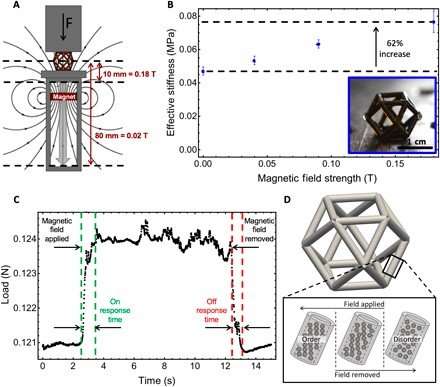

Jackson et al. tested the cuboctahedron unit cells in a custom apparatus by varying the distance of the magnet to the unit cell structure to control the magnetic field strength. They calculated the relationship between the effective Young's modulus and the magnetic field strength of the unit cell through compression tests. The response time was measured by the rate at which mechanical properties changed in the material in response to the application or removal of a magnetic field. The reversibility of the magneto-mechanical results was also tested with a strain-controlled measurement, where the cell cycled between field on/off states while under 10 percent compressive strain. The magnetic particles transitioned faster from a state of disorder to order when the magnetic field was applied.

The scientists showed the possibility of creating a larger area FRMM by printing a cuboctahedron lattice with 2 by 2 by 2 arrangement of unit cells. To produce the specimens, the drained hollow lattices were injected with MR fluid as before, but in this instance with two syringes attached to each unit cell. Once again, the stiffness response of the lattice was measured as a function of the magnetic field strength.

To observe the field response effect of the mechanical metamaterial lattice, the scientists placed a static load of 10 g mass, with an initial condition of 0.11 T maximum applied magnetic field. When the magnetic field was slowly removed, the effective stiffness decreased, deforming the lattice under the load to compress and bend. Upon complete removal of the magnet, the mass slid off the lattice surface to show the changed load-carrying ability. The FRMMs can change stiffness in a stress-controlled experiment, by solely adjusting the magnetic field. The work demonstrated the first tunable FRMMs with a dynamic range of rapid and reversible mechanical reactions in response to remotely applied magnetic fields.

The development process is agile and simple for replication, based on 3-D printing, combined with controlled fluid delivery methods to engineer a new class of microarchitectural mechanical metamaterials. Future FRMMs can be composed of active microfluidic networks to regulate the flow of MR fluids in micro-compartments for time-controlled accessibility. Magnetic shaping can increase directional control for a variety of applications. The scientists envision the use of FRMMs in a broad range of emerging applications including soft robotics, as rapidly adaptive "crash-resistant" helmets for cyclists and as noise-cancelling smart wearables.

More information: Julie A. Jackson et al. Field responsive mechanical metamaterials, Science Advances (2018). DOI: 10.1126/sciadv.aau6419

Ulrike G. K. Wegst et al. Bioinspired structural materials, Nature Materials (2014). DOI: 10.1038/nmat4089

Qi Ge et al. Multimaterial 4-D Printing with Tailorable Shape Memory Polymers, Scientific Reports (2016). DOI: 10.1038/srep31110

A. Sydney Gladman et al. Biomimetic 4-D printing, Nature Materials (2016). DOI: 10.1038/nmat4544

Journal information: Nature Materials , Scientific Reports , Science Advances

© 2018 Science X Network