Deep learning for electron microscopy

Finding defects in electron microscopy images takes months. Now, there's a faster way. It's called MENNDL, the Multinode Evolutionary Neural Networks for Deep Learning. It creates artificial neural networks—computational systems that loosely mimic the human brain—that tease defects out of dynamic data. It runs on all available nodes of the Summit supercomputer, performing 152 thousand million million calculations a second.

In mere hours, scientists using MENNDL created a neural network that performed as well as a human expert. It reduces the time to analyze electron microscopy images by months. MENNDL is the first known approach to automatically identify atomic-level structural information in scanning transmission electron microscopy data. In 2018, MENNDL received an R&D 100 award, considered the Oscars of innovation. It's also a finalist for the Gordon Bell award.

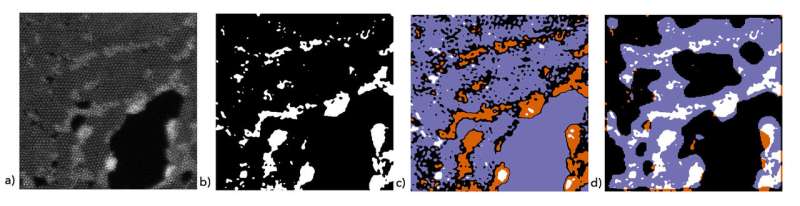

MENNDL, an artificial intelligence system, automatically designed an optimal deep learning network to extract structural information from raw atomic-resolution microscopy data. To design the network, MENNDL used 18,000 GPUs on all of the available 3000 nodes of the Summit supercomputer. In a few hours, MENNDL creates and evaluates millions of networks using a scalable, parallel, asynchronous genetic algorithm augmented with a support vector machine to automatically find a superior deep learning network topology and hyper-parameter set. This work is far faster than could be done by a human expert. For the application of electron microscopy, the system furthers the goal of better understanding the electron-beam-matter interactions and real-time image-based feedback, which enables a huge step beyond human capacity toward nanofabricating materials automatically.

More information: 167-PFlops deep learning for electron microscopy: From learning physics to atomic manipulation. SC'18: Proceedings of the International Conference for High Performance Computing, Networking, Storage and Analysis, Dallas, TX (2018).

Provided by US Department of Energy