Enhanced power factor in transparent thermoelectric nanowire materials

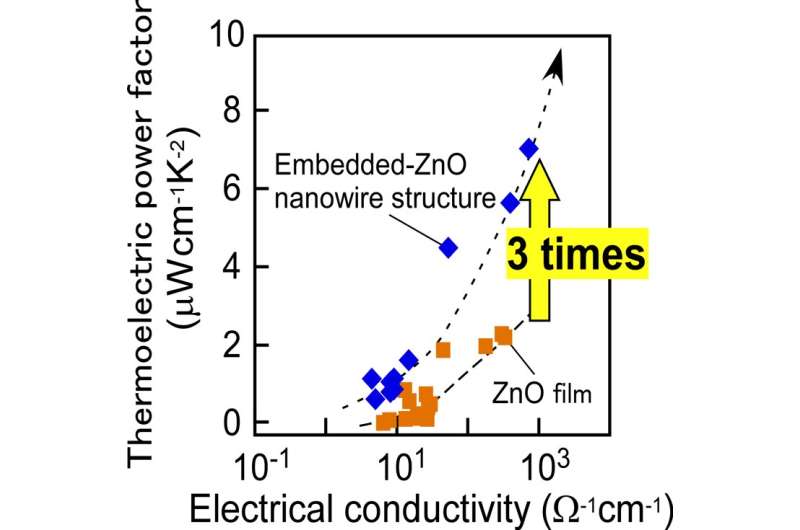

A research group led by Professor Yoshiaki Nakamura of Osaka University successfully developed a methodology for enhancing thermoelectric power factor while decreasing thermal conductivity. By introducing ZnO nanowires into ZnO films, the thermoelectric power factor became three times greater than that of ZnO film without ZnO nanowires.

For the development of high-performance thermoelectric materials, expensive and toxic heavy elements have often been used; however, the high cost and toxicity have limited the social use of such thermoelectric materials. In this research, Nakamura and his team developed novel nanostructured films (Embedded-ZnO nanowire structure) composed of low-cost and environmentally friendly ZnO. In the developed films, the thermoelectric power factor was increased by selective transmission of energetic electrons through nanowire interfaces with intentionally controlled energy barriers, and thermal conductivity was decreased by scattering phonons at the nanowire interfaces. It is anticipated that the success of this research will lead to the realization of high-performance transparent thermoelectric devices, which will enable energy recovery from transparent objects such as window glass and transparent electronic devices.

Thermoelectric generation converting heat to electricity has drawn much attention as a new energy source. Window glass with differing indoor and outdoor temperatures is anticipated as a heat source for thermoelectric generation, requiring transparent thermoelectric materials with high thermoelectric performance. Thermoelectric performance requires a high Seebeck coefficient, high electrical conductivity, and low thermal conductivity. However, these three parameters are intercorrelated, leading to difficulty in performance enhancement. So far, expensive and toxic heavy element materials with low thermal conductivity have often been used for the development of high-performance thermoelectric materials, limiting the use of thermoelectric generation. On the other hand, low-cost and environmentally friendly light element-based materials exhibit low thermoelectric performance due to their high thermal conductivity in general. However, it was reported that nanostructuring achieved a significant reduction of thermal conductivity, and light element-based materials could be candidates for thermoelectric materials. But, there is still another problem in that the nanostructure scattered not only phonons but also electrons, resulting in a reduction of thermoelectric power factor.

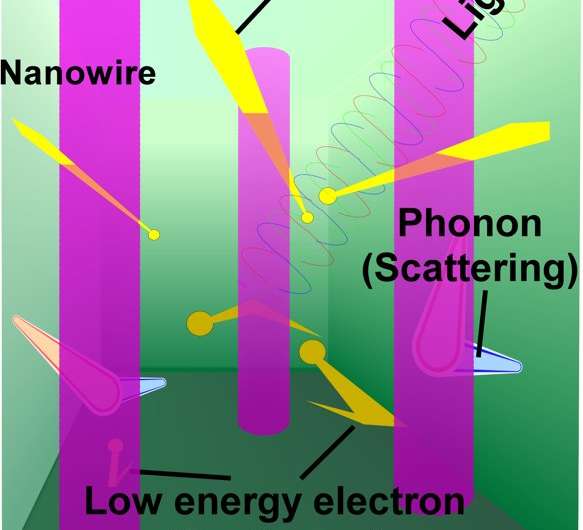

Nakamura and his team successfully developed low-cost and environmentally friendly ZnO films, including surface-controlled ZnO nanowire (Embedded-ZnO nanowire structure), for the first time in the world. Embedded-ZnO nanowire structure film with high optical transmittance in visible range is anticipated as a transparent thermoelectric material. In the structure, electron energy barrier height was controlled by modulating the dopant concentration at the nanowire interface, which enabled the increase of Seebeck coefficient due to selective transmission of high-energy electrons and scattering of low-energy electrons. High electrical conductivity is also anticipated because the ZnO crystal is epitaxially formed at the nanowire interface, leading to relatively high electrical conductivity of high-energy electrons. Furthermore, thermal conductivity is also decreased by an increase in phonon scattering at the nanowire interface (Figure 1).

Embedded-ZnO nanowire structures with nanowire areal density of more than 4×109 cm-2 exhibited a thermoelectric power factor 3 times larger than that of ZnO film without nanowires (Figure 2). It was confirmed that the dopant concentration was modulated at the interfaces by transmission electron microscopy observation of nanowire interfaces. The measurements of Seebeck coefficient and electrical conductivity in low temperature range (<300 K) showed the anomalous behaviors attributed to the electron transport controlled by energy barrier height. Furthermore, the energy barrier height was found to be several tens of meV through theoretical analysis of the experimental data. In addition, thermal conductivity of the embedded-ZnO nanowire structure was 20% smaller than that of ZnO film without nanowires because of the phonon scattering enhancement due to the introduction of the nanowire interface. These results indicate simultaneous successes: an increase of thermoelectric power factor and a decrease of thermal conductivity. The optical measurement showed that the structure had optical transmittance of about 60% in visible range, which is comparable to the value of a window of a building (Figure 3).

Future work

In the future, it will be possible to greatly decrease the thermal conductivity of embedded-ZnO nanowire structure by increasing nanowire areal density. The thermoelectric devices composed of films with this structure are expected to be realized and see widespread use due to their use of low-cost and environmentally friendly ZnO. Furthermore, the concept of "Modulating energy barrier height by controlling dopant concentration" can be applied not only to ZnO but also to other promising materials, which will accelerate the development of various high-performance thermoelectric materials.

More information: Takafumi Ishibe et al, Methodology of Thermoelectric Power Factor Enhancement by Controlling Nanowire Interface, ACS Applied Materials & Interfaces (2018). DOI: 10.1021/acsami.8b13528

Journal information: ACS Applied Materials and Interfaces

Provided by Osaka University