Team takes major step toward printed anisotropic magnets

The U.S. Department of Energy's Critical Materials Institute has taken a major step toward printed, aligned anisotropic magnets via additive manufacturing processes.

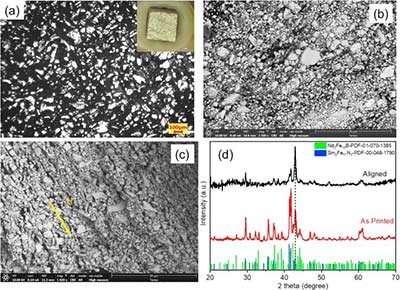

The Energy Innovation Hub manufactured hybrid nylon bonded neodymium-iron-boron and samarium-iron-nitrogen magnets using the Big Area Additive Manufacturing (BAAM) located at Oak Ridge National Laboratory.

"The application of additive manufacturing to magnet production is relatively new, and there are challenges to overcome between the nature of the process and the end properties of the product," said Ikenna Nlebedim, a scientist at the CMI.

A post-printing alignment process with applied electromagnetic fields and heat allows the researchers to tune the magnetic properties of the magnet without deforming its printed shape.

"For 3-D printed anisotropic bonded magnets, a one-step print and align process is the ultimate goal but still needs work to be successful," said Nlebedim. "We continue to pursue that goal."

By applying magnetic alignment, the researchers were able to improve magnetic performance of the already dysprosium-free composite bonded magnet without using more critical materials. "This means more economical use of expensive and critical rare earth materials," said Nlebedim.

The research is discussed in the paper, "Additive Manufacturing of anisotropic hybrid NdFeB-SmFeN nylon composite bonded magnets," co-authored by Kinjal Ghandha, Ling Li, I.C. Nlebedim, Brian K. Post, Vlastimil Kunc, Brian C. Sales, James Bell, and M. Parans Paranthaman; and published in the Journal of Magnetism and Magnetic Materials.

More information: Kinjal Gandha et al. Additive manufacturing of anisotropic hybrid NdFeB-SmFeN nylon composite bonded magnets, Journal of Magnetism and Magnetic Materials (2018). DOI: 10.1016/j.jmmm.2018.07.021

Provided by Ames Laboratory