August 16, 2018 feature

Flexible color displays with microfluidics

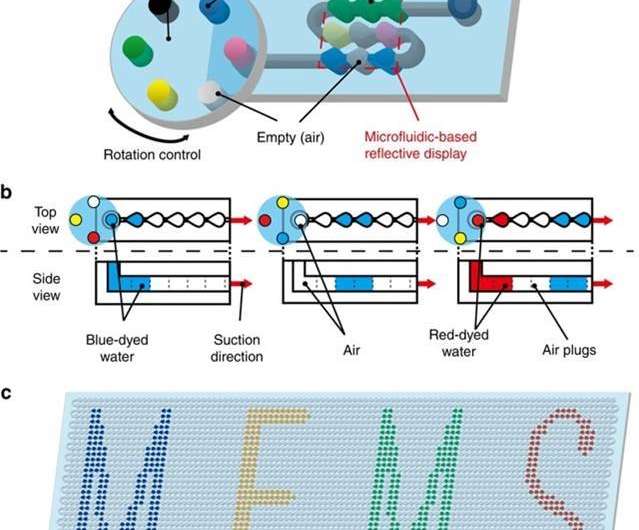

A new study published on Microsystems and Nanoengineering by Kazuhiro Kobayashi and Hiroaki Onoe details the development of a flexible and reflective multicolor display system that does not require continued energy supply for color retention. The idea aims to find futuristic applications with sustainable color displays and replace existing electronic display signs currently used for multicolor messages and images. While the concept originates from electronic paper or flexible electronics that look like print on paper (developed for smart wear), the proposed method simply relies on sequentially introduced colored water droplets and air pockets in a microfluidic device precisely fabricated on a flexible polymer to maintain stable bitmap images without energy consumption.

The method also deviates from existing techniques of liquid crystals or organic light emitting diodes (OLEDs), which consume energy at the level of the light-emitting pixel. The technique houses a microfluidic water droplet train as a flexible, reflective display. The working principle of the system is based on a rotary liquid selector with suction-based negative pressure to drive the droplets in the intended direction and form a predetermined sign.

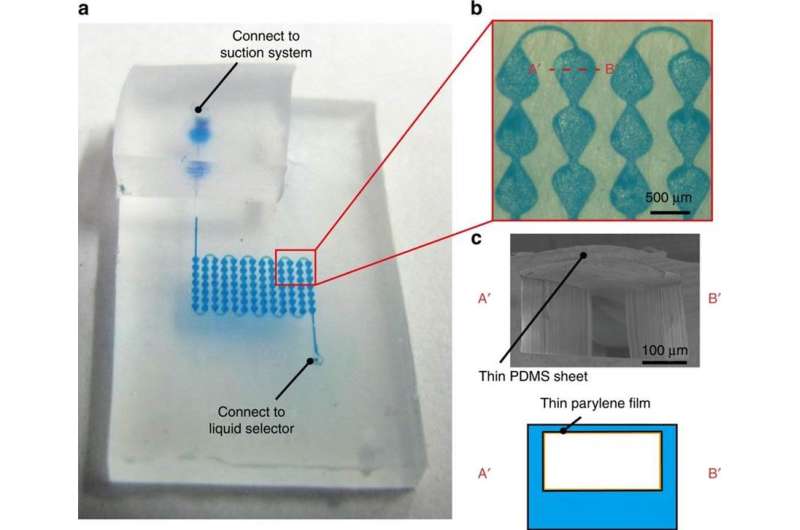

Microchannels of the proposed device were fabricated with the flexible polymer, polydimethylsiloxane (PDMS), a material with properties that include transparency under visible light and permeability to air. The authors used soft lithography and bonding techniques to create PDMS-PDMS microchannels with pixel patterns ranging from 400-800 μm in diameter and 50-200 μm in height. In the device architecture, the patterns were connected via linear channels of 100-200 μm in width. Since the material is permeable to air and gas soluble, a thin Parylene layer (500 nm thick) was deposited within the microchannels to prevent the leakage and evaporation of air and water.

To fabricate an optimized pixel size, the authors devised a relationship between the microchannel geometry and water loss in order to maintain a specific volume of dyed water as droplets advanced in the device. The device design and optimization included measurements of the minimal differential pressure required to drive dyed water droplets through the microchannels. The pressure within the microfluidic device suction system was controlled with a computer-aided valve system, and the switch control was programmed using MATLAB. In addition, the capacity for color switching and droplet control was assessed at the level of the single pixel for optimized image display. The relationship between droplet position and the time of negative pressure applied was optimized to indicate that the device could be controlled at the level of the single pixel.

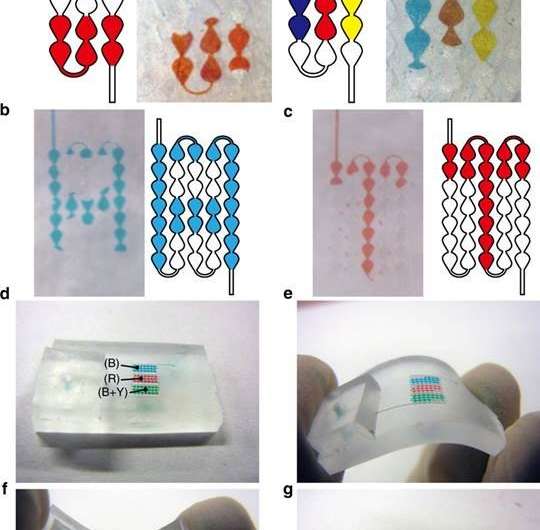

In the study, a range of images were created in this way in zig-zag microchannels as proof of principle to test the proposed concept of flexible multicolor reflective displays. Color retention was enabled by stopping the suction system, during which the orientation of the display remained intact without energy supply.

Experimental results validated that the system could display multicolored reflective images and retain them without energy consumption as theorized. The images were durable while maintaining their position after pliable twisting, to indicate flexibility and recovery of the original multicolored framework. The scientists predict that such flexible and energy-less display systems may find innovative applications on robot skins, clothes and accessories in daily life in the future.

More information: Kazuhiro Kobayashi et al. Microfluidic-based flexible reflective multicolor display, Microsystems & Nanoengineering (2018). DOI: 10.1038/s41378-018-0018-1

Power-free poly(dimethylsiloxane) microfluidic devices for gold nanoparticle-based DNA analysis dx.doi.org/10.1039%2Fb403930k, Hosokawa et al, 2004, Royal Society of Chemistry, Lab on a Chip.

Two-dimensional flexible nanoelectronics, www.nature.com/articles/ncomms6678, Akinwande et al, Review, December 2014, Nature Communications.

All-organic active matrix flexible display aip.scitation.org/doi/abs/10.1 … 8213?journalCode=apl Zhou L et al, 2006 Appl. Phys. Lett.

Organic thin-film transistor-driven polymer-dispersed liquid crystal displays on flexible polymer substrates aip.scitation.org/doi/10.1063/1.1448659, Sheraw et al, 2002, Appl. Phys. Lett.

PDMS-based micro PCR chip with Parylene coating iopscience.iop.org/article/10. … 60-1317/13/5/332/pdf, Shin et al, 2003, J. Micromech. Microeng.

Electronic paper: flexible active-matrix electronic ink display www.nature.com/articles/423136a Chen, et al, Brief Communication, May 2003, Nature.

Journal information: Nature Communications , Lab on a Chip , Applied Physics Letters , Nature

© 2018 Phys.org