January 26, 2018 report

Flow apparatus samples up to 1500 chemical reactions a day

A team of researchers at Pfizer, the pharmaceutical giant, has developed an automated flow chemistry system that is capable of carrying out 1500 reactions over a 24-hour period. In their paper published in the journal Science, the group describes the system, how well it tested and its limitations.

Developing new drugs to treat human ailments is both expensive and profitable—researchers at pharmaceutical giants such as Pfizer are constantly looking for ways to develop new drugs that cost less which, in turn, will increase profits. In this new effort, the team at Pfizer built a machine that allows researchers to carry out and sample reactions every 45 seconds.

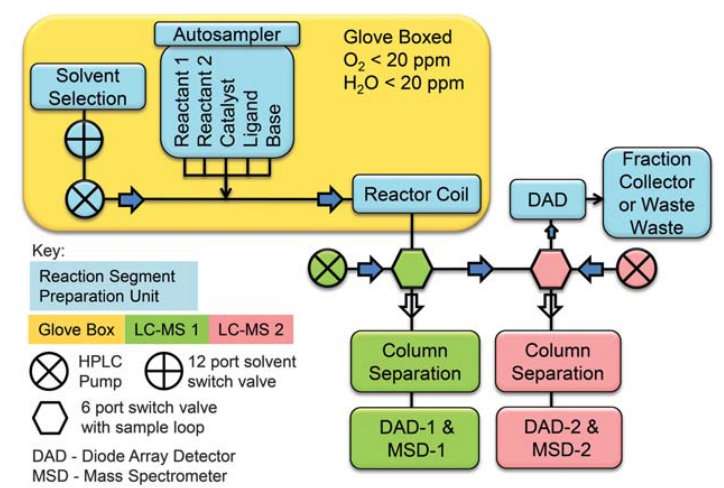

At its most basic level, a lot of what pharmaceutical researchers do involves optimizing chemical reactions to discover which is best for scaling up for testing and producing commercial drugs—a process that is notoriously expensive because it is so time consuming. To speed things up, the researchers devised a platform that supports continuous flow of chemicals through a reactor coil for precise control of residence time, rate of flow, pressure and temperature. It also hosts two ultrahigh performance liquid chromatography devices, one for analyzing reagents, the other for analyzing the reagents as they emerge. The setup allows for pipetting reagents into solvent samples at nanoliter volumes prior to analysis with the chromatography devices.

The researchers select a carrier solvent to flow through the device and then engage the sample device, which injects tiny amounts of reagents into similarly tiny samples of the solvent, and then test it to see what happens. They tested the system by carrying out 5,760 Suzuki-Miyaura coupling reactions with a host of reagents under varying conditions in just four days.

The researchers note that while useful, the device is not suitable for use in commercial applications, in part because it cannot handle heterogeneous or biphasic mixes. They will continue to work with the device, hoping to expand its capabilities, and suggest other researchers might want to build similar systems for testing of their own ideas.

More information: Damith Perera et al. A platform for automated nanomole-scale reaction screening and micromole-scale synthesis in flow, Science (2018). DOI: 10.1126/science.aap9112

Abstract

The scarcity of complex intermediates in pharmaceutical research motivates the pursuit of reaction optimization protocols on submilligram scales. We report here the development of an automated flow-based synthesis platform, designed from commercially available components, that integrates both rapid nanomole-scale reaction screening and micromole-scale synthesis into a single modular unit. This system was validated by exploring a diverse range of reaction variables in a Suzuki-Miyaura coupling on nanomole scale at elevated temperatures, generating liquid chromatography–mass spectrometry data points for 5760 reactions at a rate of >1500 reactions per 24 hours. Through multiple injections of the same segment, the system directly produced micromole quantities of desired material. The optimal conditions were also replicated in traditional flow and batch mode at 50- to 200-milligram scale to provide good to excellent yields.

Journal information: Science

© 2018 Phys.org